| Availability: | |

|---|---|

| Quantity: | |

RB-H5-2540-Z11

RBT

8465990000

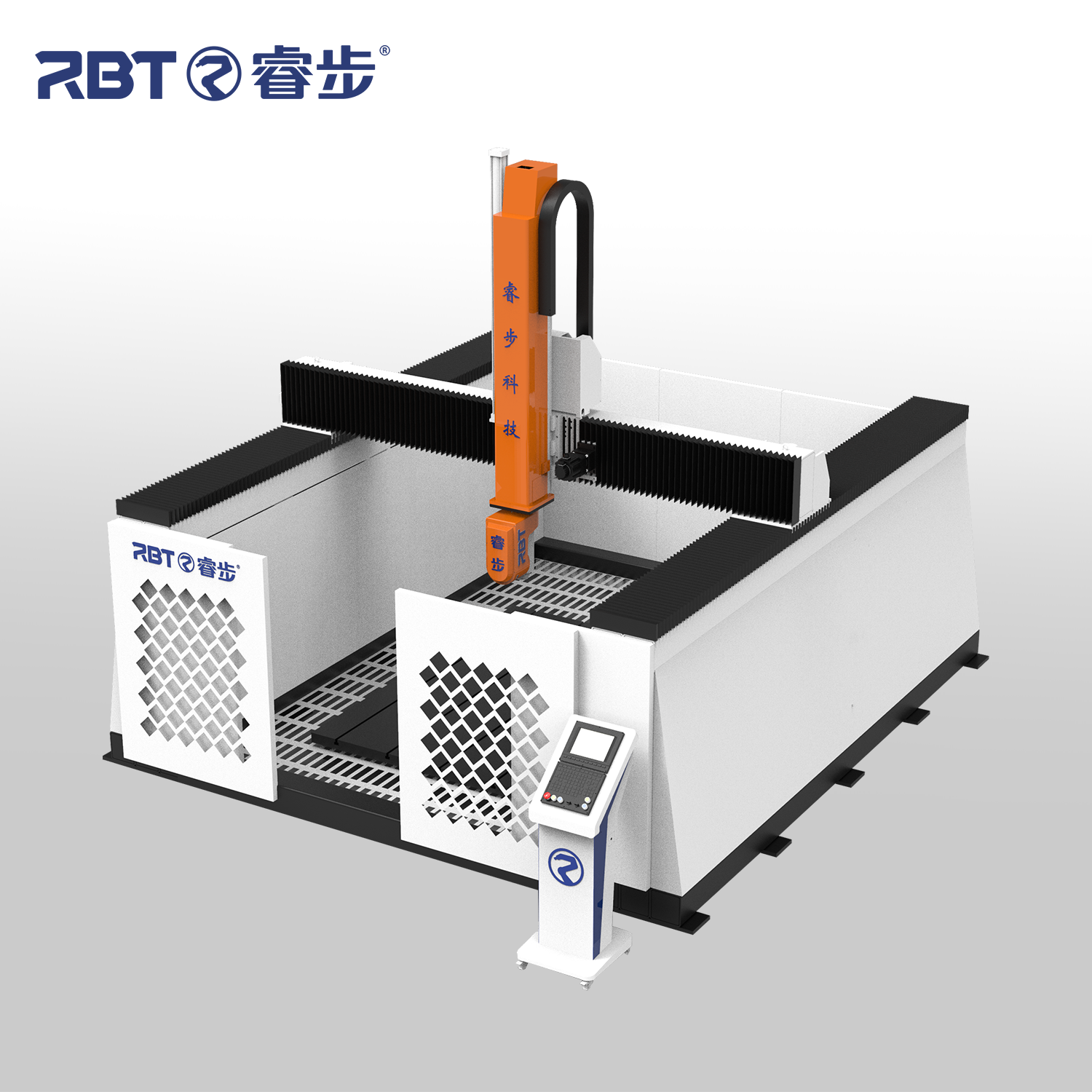

Five-axis Cnc Machining Center for Aluminum Mold Making CE Approved

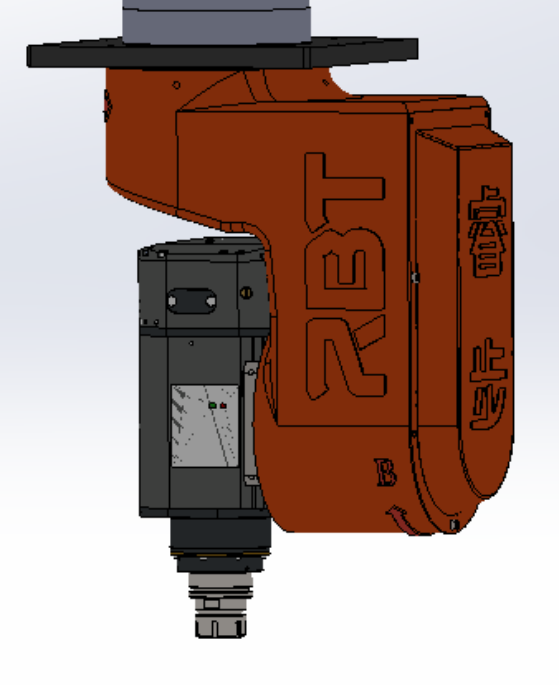

1. Adjustable Heavy Duty Spindle: The five-axis milling machine spindle for aluminum mold machining is a high-precision, rigid tool capable of complex multi-directional cutting. It is designed to efficiently and smoothly machine complex molds, minimize material waste, and ensure accuracy and surface finish. We offer RBT brand or Italian/German imported spindles for customers to choose. This versatile spindle can be used for five-axis CNC routers or five-axis CNC machines, meeting the precision and durability needs of various industrial applications.

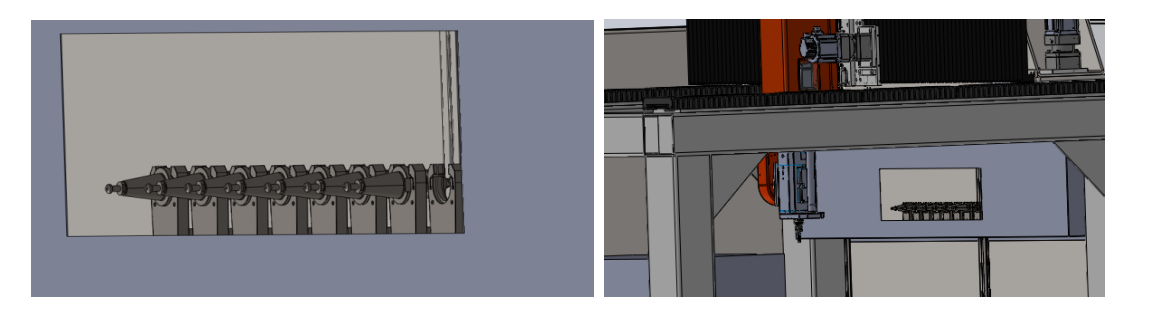

2. Automatic Tool Changer System (ATC): Equipped with a 8-12 clamp tool magazine, automatic tool changing and precision centering ensure seamless, unattended machining of workpieces from start to finish in one fixture setup. This feature improves the efficiency of CNC milling machines, making it ideal for rapid prototype CNC machining and complex five-axis CNC machine tasks.

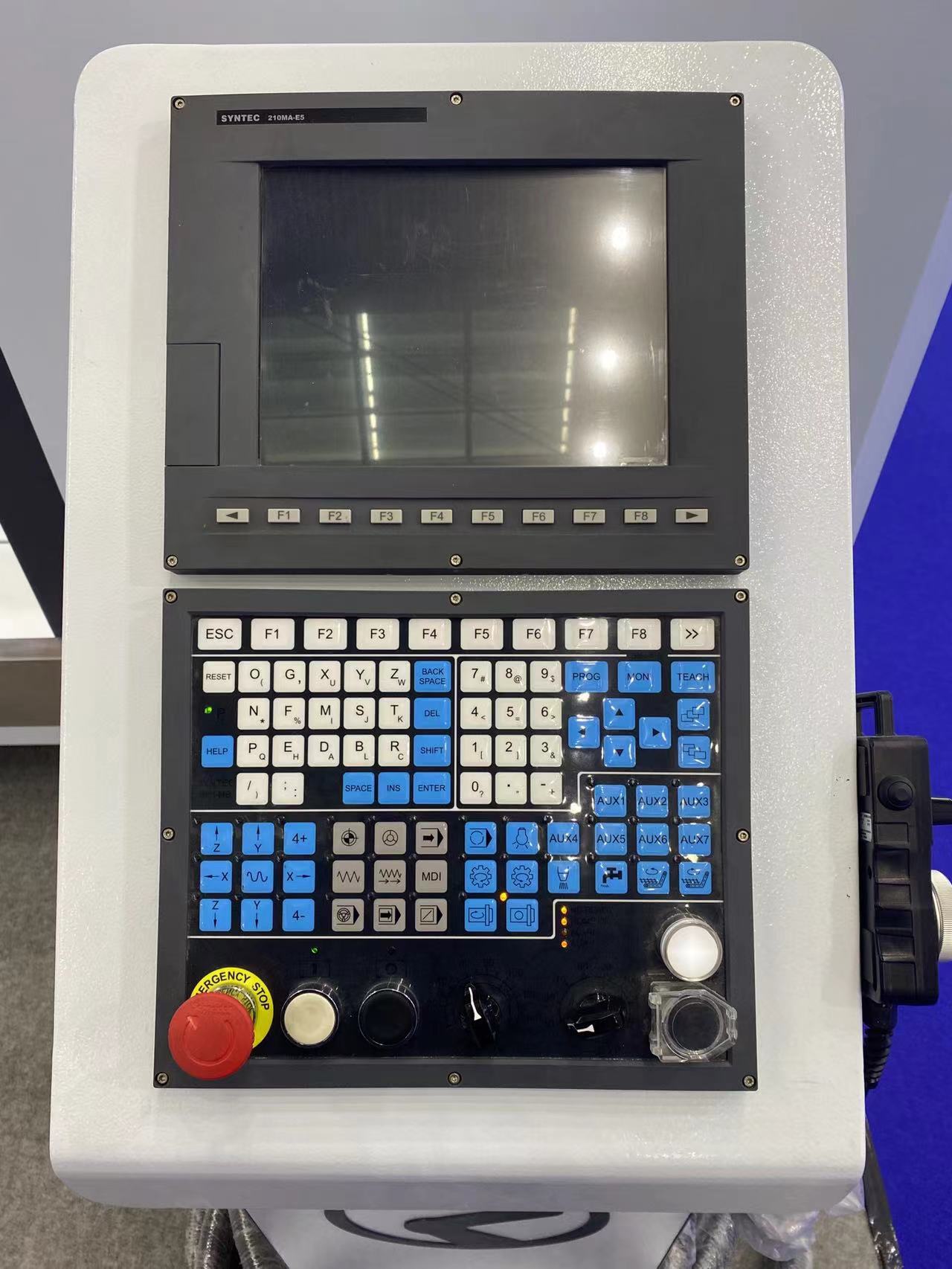

3. Multifunctional CNC Control System: Taiwan Syntec five-axis CNC control system is a cutting-edge control solution known for its user-friendly interface and advanced functions. It integrates seamlessly with multi-axis machines to achieve complex part programming and tool path optimization. The system provides high-speed processing, precise motion control and real-time feedback to improve machining accuracy.

4. Program: Powerful CAD/CAM integrated software support enables Syntec systems to improve efficiency and productivity in five-axis machining environments, suitable for a wide range of applications from mold manufacturing to aviation components. Other CNC systems such as Mitsubishi, Siemens and Fanuc are also feasible, ensuring compatibility with a variety of compound five-axis CNC machine models.

5. Water circulation table: Meet the flushable processing of aluminum molds.

6. Transmission components:

X/Y/Z axis adopts Taiwan HIWIN roller linear guide, double-row and six-row sliders, with strong load capacity and suitable for heavy-duty cutting.

The X/Y/Z axis uses Taiwan TBI precision ground gears and racks, with small backlash, high precision and stable operation;

The X/Y axis uses Japan Shimpo reducer;

The C/B axis uses Japan Sumitomo precision hollow reducer.

Technical Parameters

Application of 5 Axis CNC Machining Center

CNC milling machines are designed for the rapid machining of molds and patterns in materials such as foam, wood, resin, plaster, aluminum, etc. These 5-axis CNC machining centers are designed to be much faster than traditional metalworking CNC milling machines, providing a high-speed alternative for material processing.

CE Approved 5 Axis CNC Machining Center

Clients

RBT Factory and team