| Availability: | |

|---|---|

| Quantity: | |

RB-F5-1930-Z08

RBT

8465990000

Five-Axis CNC Machine

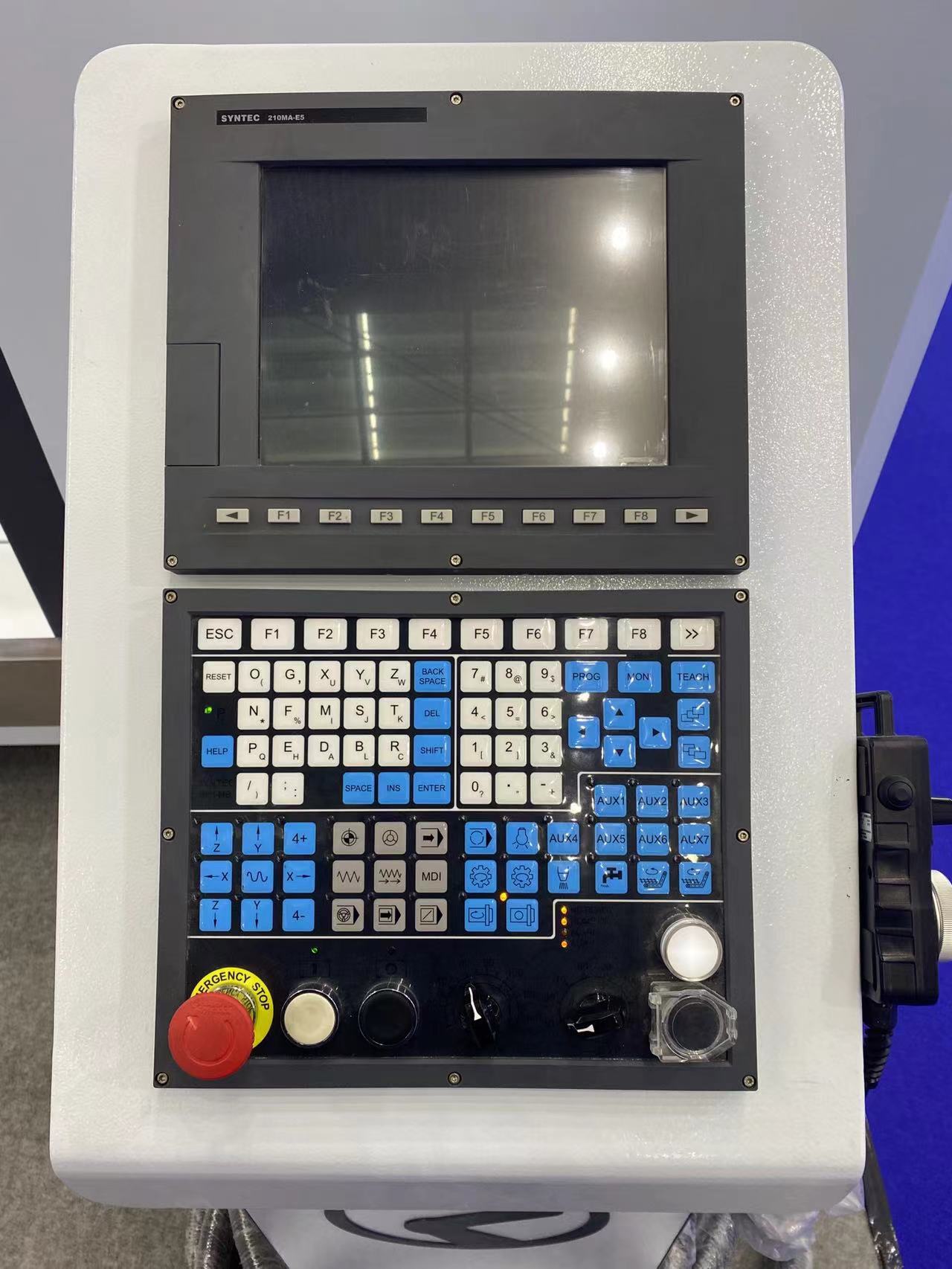

1. The system adopts the SYNEC five-axis linkage CNC system,which has great advantages in terms of function, stability and after-sales service; Support five-axis machining; The operation and application functions are simple and easy to learn. It can be equipped with RTCP function.

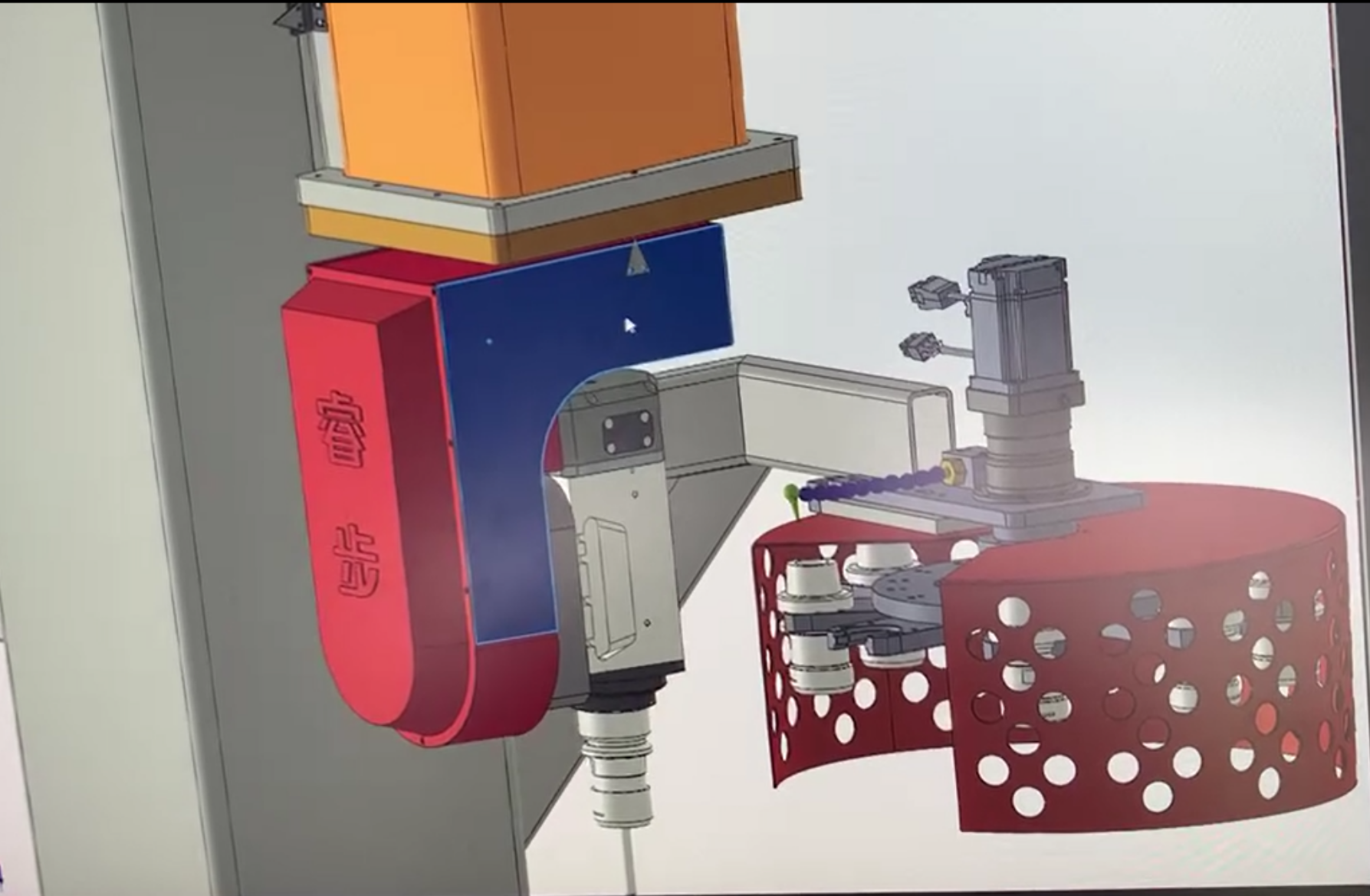

2. The milling head has 2 CNC continuous rotary coordinates: the 4th (C) axis and the 5th (B) axis, realizing linkage processing (including milling, hole punching and edge cutting or trimming functions). The combination of these two rotary axes with the linear axes (X, Y, and Z) provides a high degree of flexibility and precision in manufacturing, allowing for the creation of intricate parts and components that would be difficult or impossible to produce with a machine that has fewer axes of motion.

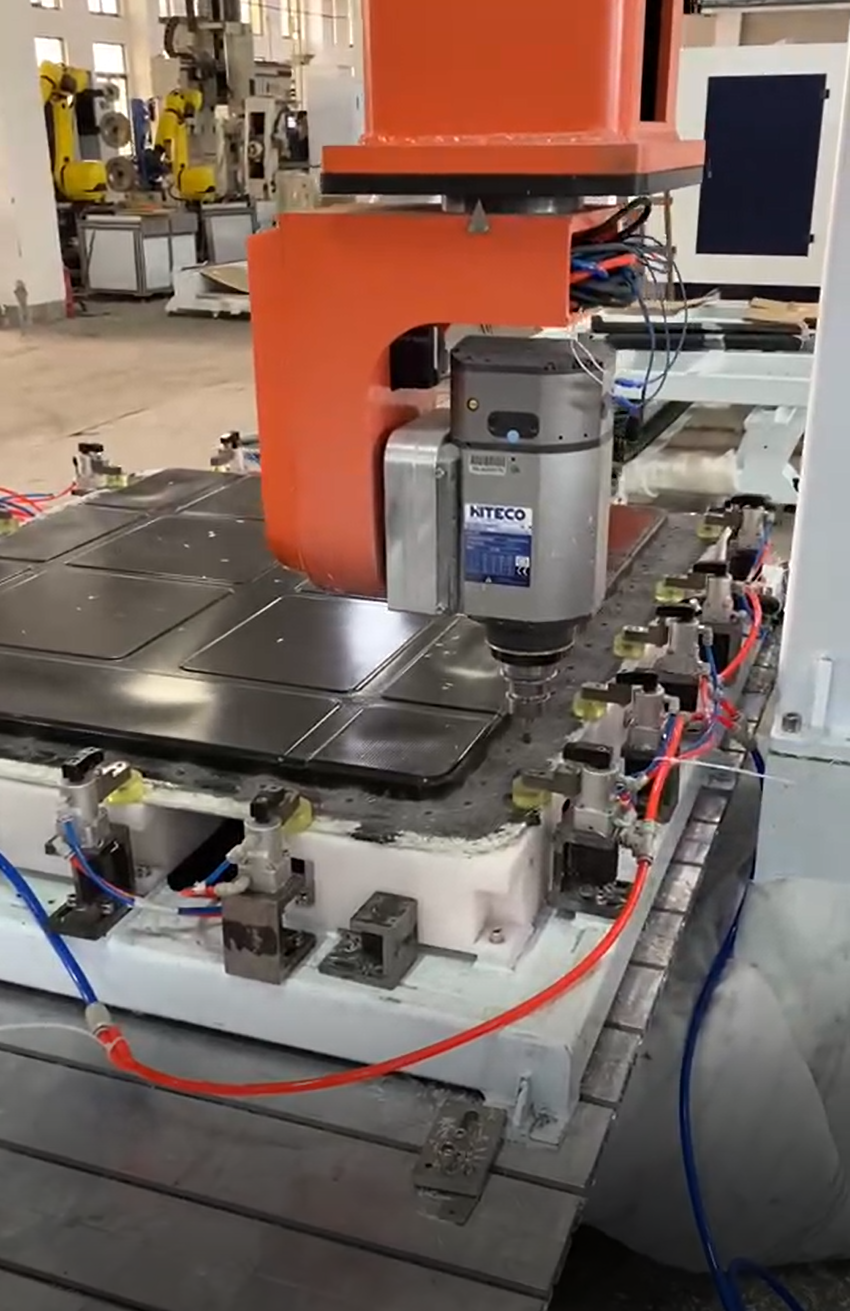

RBT independently developed and produced spindle or Germany/ Italy/ Korea imported spindle such as HSM, Hiteco, HSD for option.

3. The multi-face processing of the entire product can be completed in one time clamping with high processing precision, efficient and accurate positioning.

RBT is experienced in fixture including pneumatic, vacuum, hydraulic and mechanical types, qualified for customized design based on user's digital model.

4. The tool magazine of a 5-axis CNC machine is a storage unit that holds multiple cutting tools, allowing for automatic tool changes during machining, enhancing efficiency and reducing setup time.

Technical Parameter

No. | Items | Parameter | No. | Items | Parameter |

1 | product name | FIVE-AXIS CNC MACHINE | 9 | Z axis maximum speed | 20m/min |

2 | model | RB-F5-1930-Z08 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

3 | X axis effective stroke | 1900mm | 11 | voltage | 380V |

4 | Y axis effective stroke | 3000mm | 12 | total power | 14.5KW |

5 | Z axis effective stroke | 800mm | 13 | spindle power | 5.5KW(customizable) |

6 | B-axis rotation angle | ±130° | 14 | Frequency | 50HZ |

7 | C-axis rotation angle | ±540° | 15 | weight | 3.5T |

8 | X/Y axis maximum speed | 35m/min | 16 | size | L5100*W2610*H3982mm |

Machine applicable to

Composite materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass fiber, carbon/carbon, etc.;

Plastics: ABS, PVC, PC, PP, PS, PE, PET, HDPE, PETG, Acrylic etc.;

Other non-metal material: high-density sponge, Styrofoam foam, wood, substitute wood, stone, plaster etc

Machine widely used in

Mold manufacturing, composite material processing, and thick sheet thermoforming processing in industries such as aerospace, rail transit, automotive interior and exterior, sporting goods, medical beauty, white goods, handicrafts, and sanitary ware.

Laser interferometer test to verify the precision of a 5-axis CNC machine

The assembly process is strictly in accordance with the standards of CNC machine tools, and laser trackers, British Renishaw ballbars, etc. are used for machine inspection and error compensation to ensure assembly accuracy.

CE Certified 5 axis cnc machine

Representative Customer

Cooperation Cases

Here are some hypothetical examples of customization projects for 5-axis CNC machines:

BYD (Automotive and Energy Company):

Customized 5-axis CNC machines for BYD could be equipped with high-precision tools for the production of intricate electric vehicle components, such as battery casings and complex housings for electric motors.

Benz (Automotive Luxury Brand):

For Benz, customized machines might feature advanced software integration for the production of luxury car interior components with high-quality finishes, ensuring the perfect fit and aesthetic appeal.

Boeing (Aerospace and Defense Corporation):

Boeing could utilize customized 5-axis CNC machines with robust fixtures and tooling designed for the precise milling of aircraft parts from composite materials, such as wing components and engine housings.

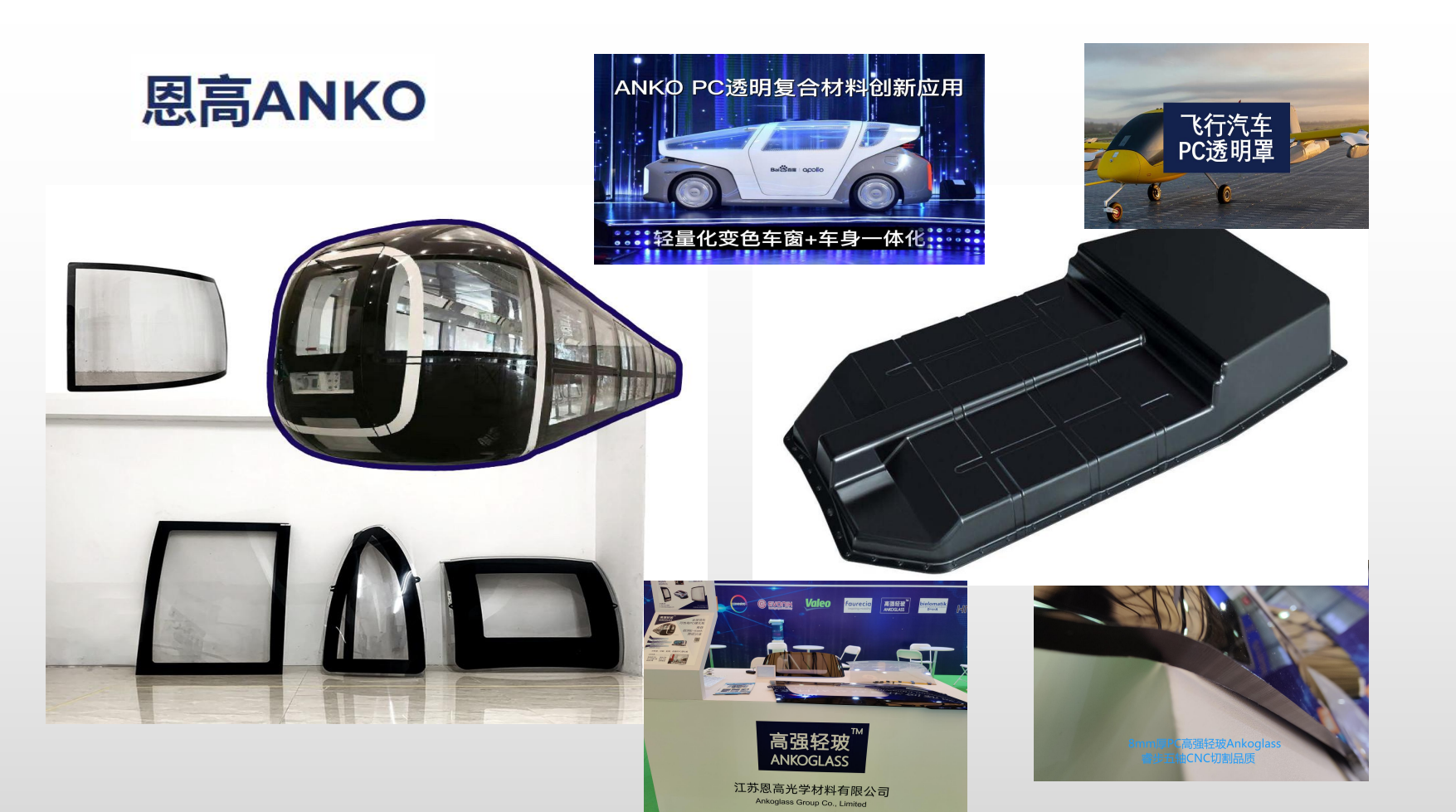

ANKO GLASS Customization Project:

ANKO GLASS required a 5-axis CNC machine capable of handling the complexities of glassfiber part manufacturing.

Packing & Delivery