| Availability: | |

|---|---|

| Quantity: | |

RB-H6-3626-Z12

RBT

8465990000

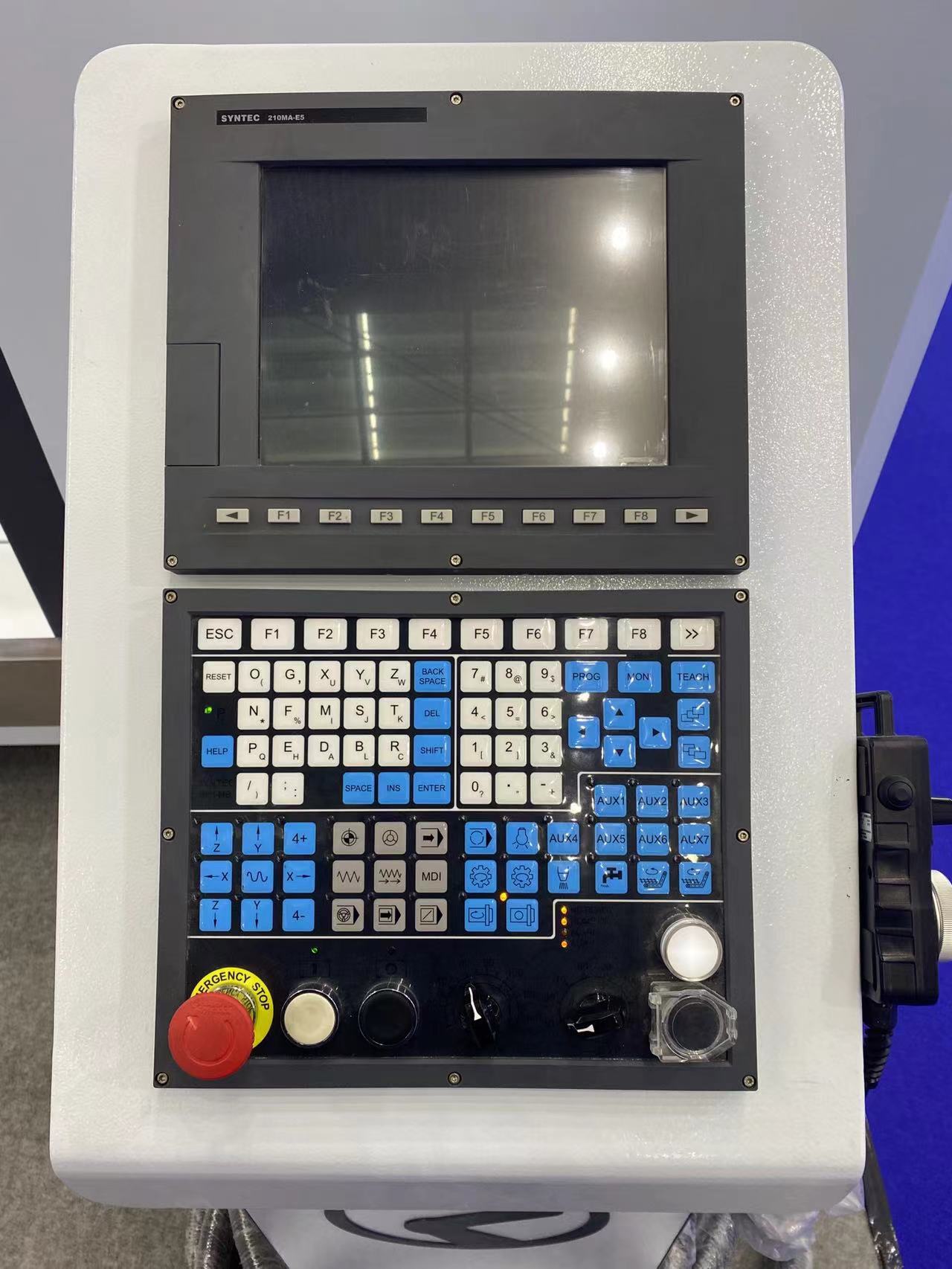

1. CNC system

Adopts SYNEC five-axis linkage CNC system, providing important advantages in functionality, stability and after-sales support. Supports five-axis machining, user-friendly operation and application characteristics.

2. Milling head rotation coordinates

The milling head has two CNC rotation coordinates that can rotate continuously: the fourth axis (C axis) and the fifth axis (B axis). This allows coordinated processing, including cutting, punching and trimming. The entire product can be processed on multiple faces in one clamping, ensuring high precision, efficient operation and accurate positioning.

3. Spindle

Provide self-produced RBT spindles and high-quality imported options from well-known manufacturers HSM, Hiteco, HSD from Germany, Italy and South Korea to meet different performance requirements.

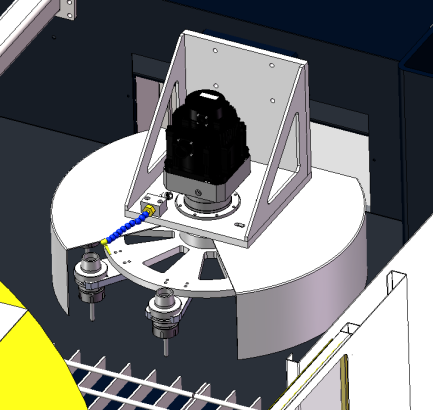

4. Tool magazine

The tool library of the five-axis CNC machine is a unit that stores multiple cutting tools, allowing automatic tool change during machining, improving efficiency and reducing setup time.

5. Dual-table operation

The two tables operate independently, one table handles machining tasks and the other table handles loading and unloading.Two workbenches can be operated simultaneously as a large single workbench to process large products.

6. Truss-type protective chamber structure:

Meet the safety protection and chip prevention needs during the production process; the ground drainage dust removal device cooperates with the high-performance dust collector to collect external processing debris.

Technical Parameter

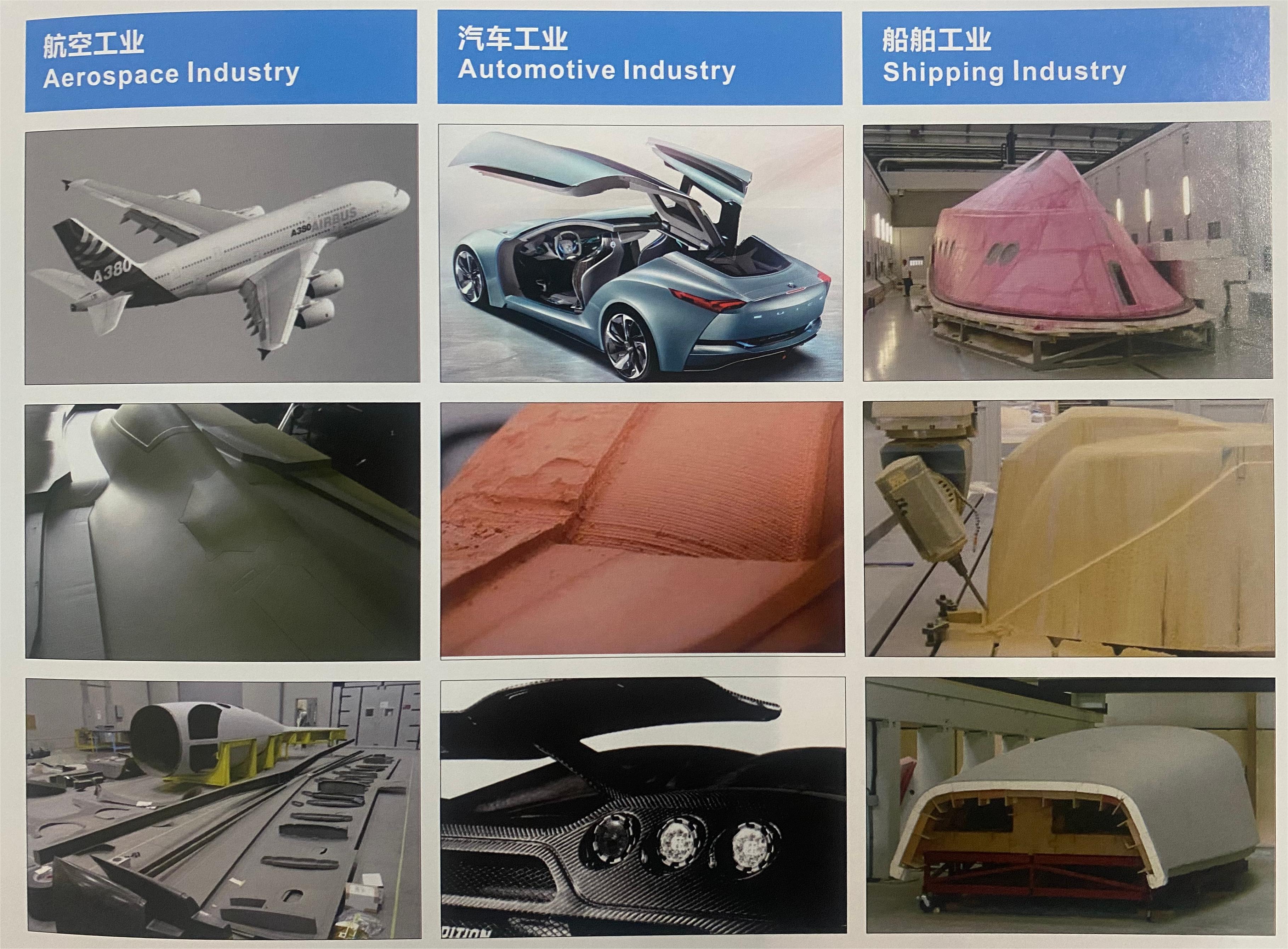

5 Axis CNC Router for Plastic and Composite

5 Axis CNC Router for Aerospace, Automotive and Shipping

How to make sure the accuracy of a 5 axis cnc router?

The assembly process is strictly in accordance with the standards of CNC machine tools, and laser trackers, British Renishaw ballbars, etc. are used for machine inspection and error compensation to ensure assembly accuracy.

BYD & RBT 5 Axis CNC Router

RBT 5-axis CNC machine precisely processes BYD vehicle battery covers, ensuring high-precision contours and complex geometries that meet stringent automotive standards for quality and durability.