| Availability: | |

|---|---|

| Quantity: | |

RB-F6-2520-Z08

RBT

The Twin Table 5 Axis CNC Router features a dual workbench system that significantly enhances production efficiency. With two independent workbenches, one table can be machined while the other is loaded or unloaded, allowing continuous production. These workbenches can also be combined into one large table, making it an ideal 5 Axis CNC Machining Center for processing larger products. This design reduces downtime and boosts productivity.

Equipped with a SYNEC 5 Axis CNC Cutting Machine, this router excels in complex machining tasks such as drilling, punching, cutting, and trimming. The advanced five-axis linkage system ensures high-speed processing, precision, and comprehensive programming support for intricate part production, making it suitable for industries like 5 Axis CNC Router for Medical applications.

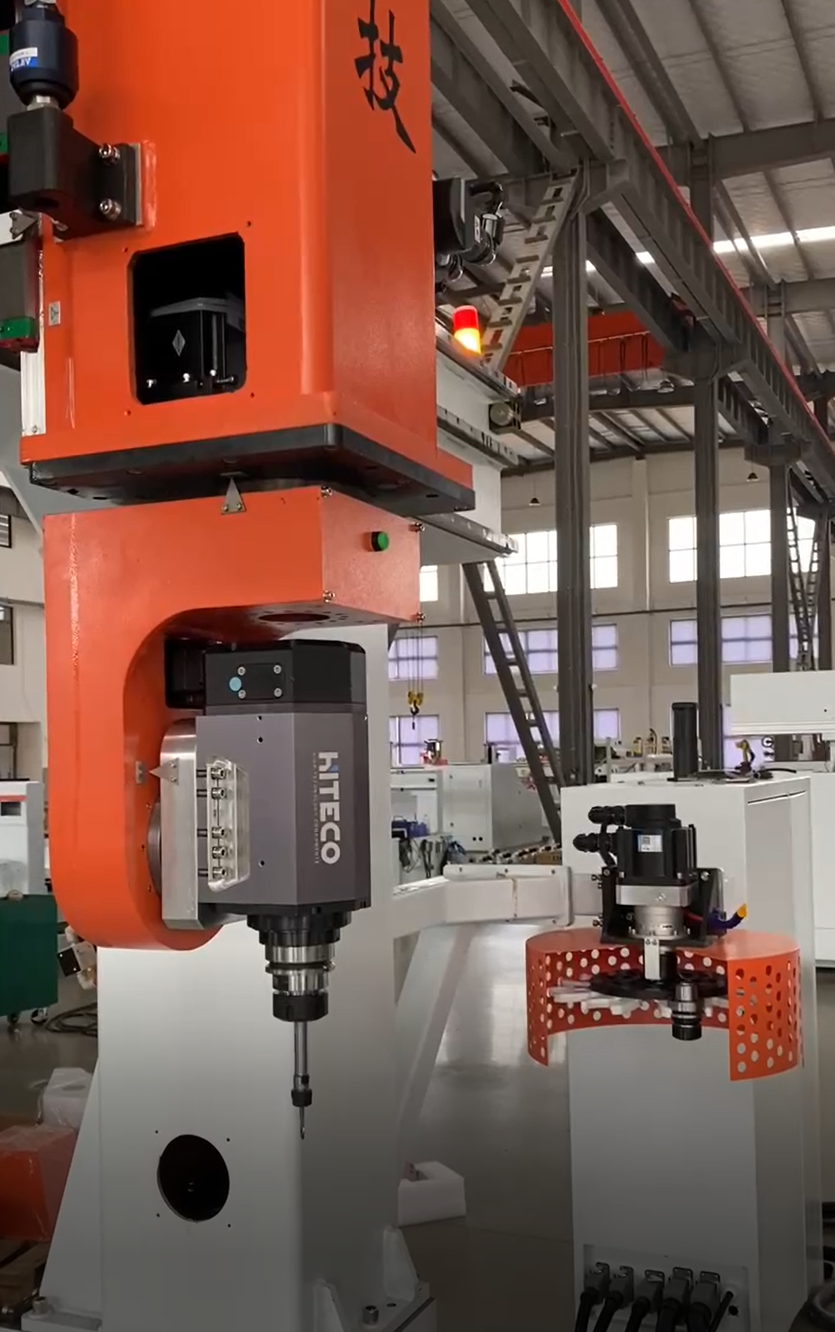

This 5 Axis CNC Milling Machine includes 3 linear (X, Y, Z) axes and 2 rotational (A and B or C) axes. The machine offers reliable performance with its in-house brand spindles, along with premium imported options like Italy's Hiteco, enhancing its capabilities for use in 5 Axis CNC Router for Aerospace sectors.

The machine comes with an 8-clamp tool magazine that stores a variety of cutting tools, ensuring seamless and automated tool transitions. This feature optimizes workflow, minimizes downtime, and is essential for any modern CNC Milling Center.

Utilizing Taiwan HIWIN roller linear guides for the X/Y/Z axes and a Japanese Sumitomo Precision hollow reducer for the C/B axis, this 5 Axis CNC Machine guarantees heavy-duty cutting and reliable performance.

The 5 Axis CNC Router is built with a solid welded steel bed, reinforced with ribbed plates. All bed components undergo stress-relieving treatment, providing a stable foundation for precise machining.

Incorporating laser interferometer detection, the CNC Machining Center ensures high machine accuracy, meeting stringent industry standards.

This 5 Axis CNC Milling Machine comes with a CE Certificate, signifying compliance with European safety, health, and environmental protection standards, making it a reliable choice for any CNC cutting operation.

Technical Parameter of Twin-table 5-axis CNC Router

No. | Items | Parameter | No. | Items | Parameter |

1 | Product name | Twin table 5-axis CNC Machining Center | 9 | Z axis maximum speed | 20m/min |

2 | model | RB-F6-2520-Z08 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

3 | X axis effective stroke | 2500mm | 11 | voltage | 380V |

4 | Y axis effective stroke | 2000mm | 12 | total power | 14.5KW |

5 | Z axis effective stroke | 820mm | 13 | spindle power | 5.5KW(customizable) |

6 | B-axis rotation angle | ±130° | 14 | Frequency | 50HZ |

7 | C-axis rotation angle | ±540° | 15 | weight | 4.1T |

8 | X/Y axis maximum speed | 35m/min | 16 | size | L3482*W3350*H3768mm |

A five-axis CNC router is a versatile machine that can handle a wide range of materials

1. Plastics: ABS, PVC, polycarbonate (PC), polypropylene (PP), polystyrene (PS), polyethylene (PE), PET, HDPE, PETG, acrylic, and more.

2. Composite Materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass fiber, and carbon/carbon composites.

3. Wood: Solid woods, plywood, MDF (medium-density fiberboard), and other wood-based materials.

4. Soft metals : aluminum, copper, zinc, making it suitable for lightweight parts and structures.

5. Aluminum / Paper Honeycomb

6. High-Density Sponge , Styrofoam Foam , Plaster, for creating molds or castings.

7.Resin: Used in various applications, including casting and 3D printing, resin can be shaped by a CNC router.

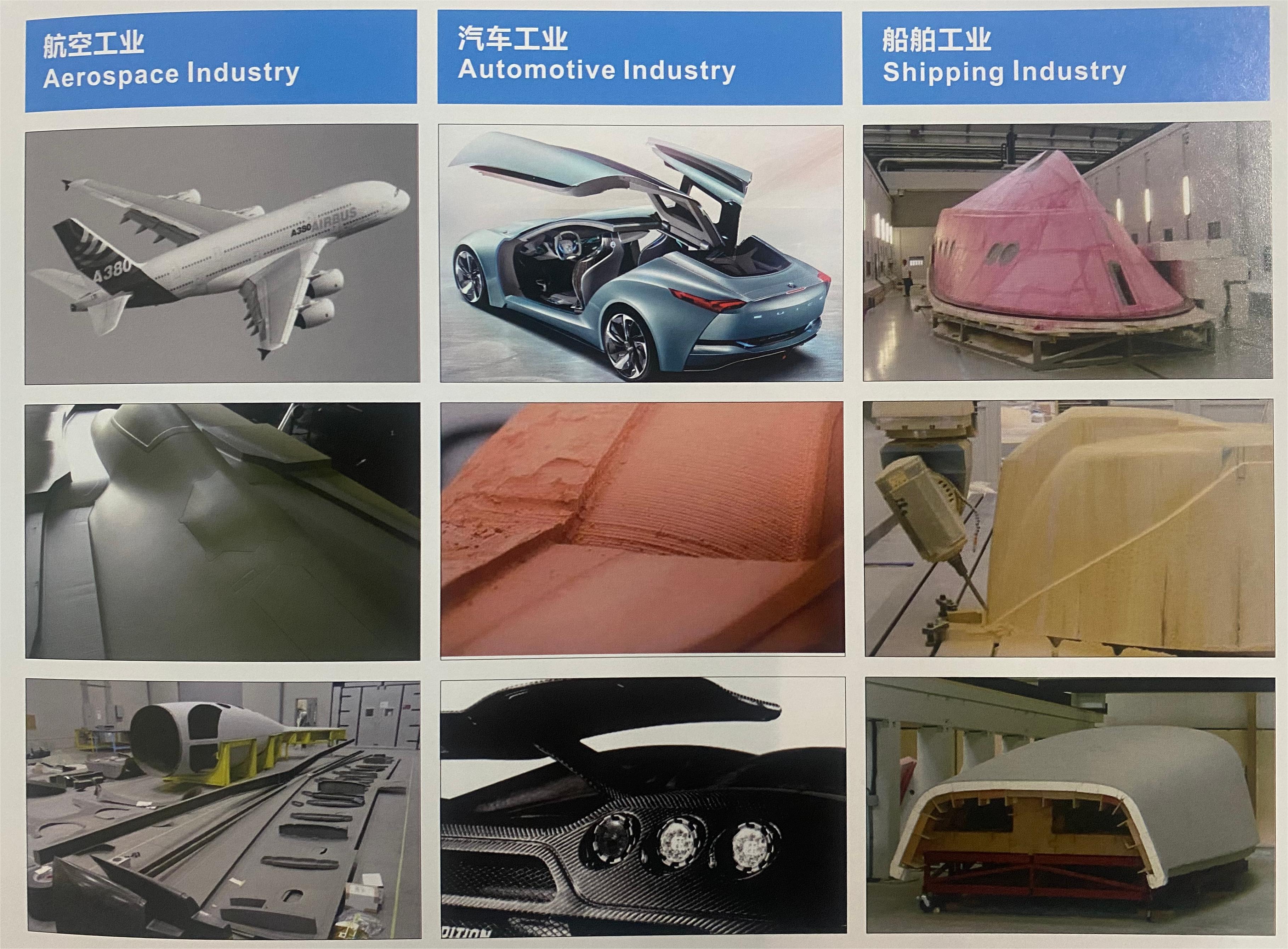

5-axis CNC router is utilized across a wide range of industries

1. Aerospace: For the manufacturing of complex aircraft components, such as engine parts, wing components, and interior fittings.

2. Automotive: To produce intricate parts for cars and trucks, including engine parts, suspension components, and interior trim.

3. Medical: For the precision machining of medical instruments, prosthetics, and dental appliances.

4. Mold and Die Making: To create complex molds and dies for injection molding, blow molding, and other manufacturing processes.

5. Woodworking: For high-precision cutting and carving in furniture making, cabinetry, and architectural woodworking.

6. Rapid Prototyping: To quickly produce prototypes for product development, allowing designers to iterate and refine their designs.

7. Marine: For the production of complex boat and ship components, such as hull parts, propellers, and interior fittings.

8. Energy For components in wind turbines, solar panels, and other energy-related equipment.

9. Packaging: For the production of complex packaging machinery and molds.

10.Sign Making: For creating three-dimensional signs and displays with complex shapes.

Precision test by laser interferometer

CE approved 5 Axis CNC Router

Cooperation cases

Factory Overview

Packing & Delivery