| Availability: | |

|---|---|

| Quantity: | |

RB-F6-2520-Z08

RBT

8465990000

The Twin Table Five-Axis CNC Router is actually crafted to satisfy the needs of modern-day production, especially in industries demanding high precision and convenience. Along with the combination of the Syntec CNC unit coming from Taiwan, an user-friendly however, sophisticated command user interface, this device is actually improved for Composite 5-Axis CNC Routers. The system guarantees high-speed handling and precision machining, making it ideal for complex part manufacturing, especially when partnering with composite products. This sophisticated control device is actually crucial for those hoping to accomplish meticulous cause markets such as aerospace, auto, and high-tech manufacturing.

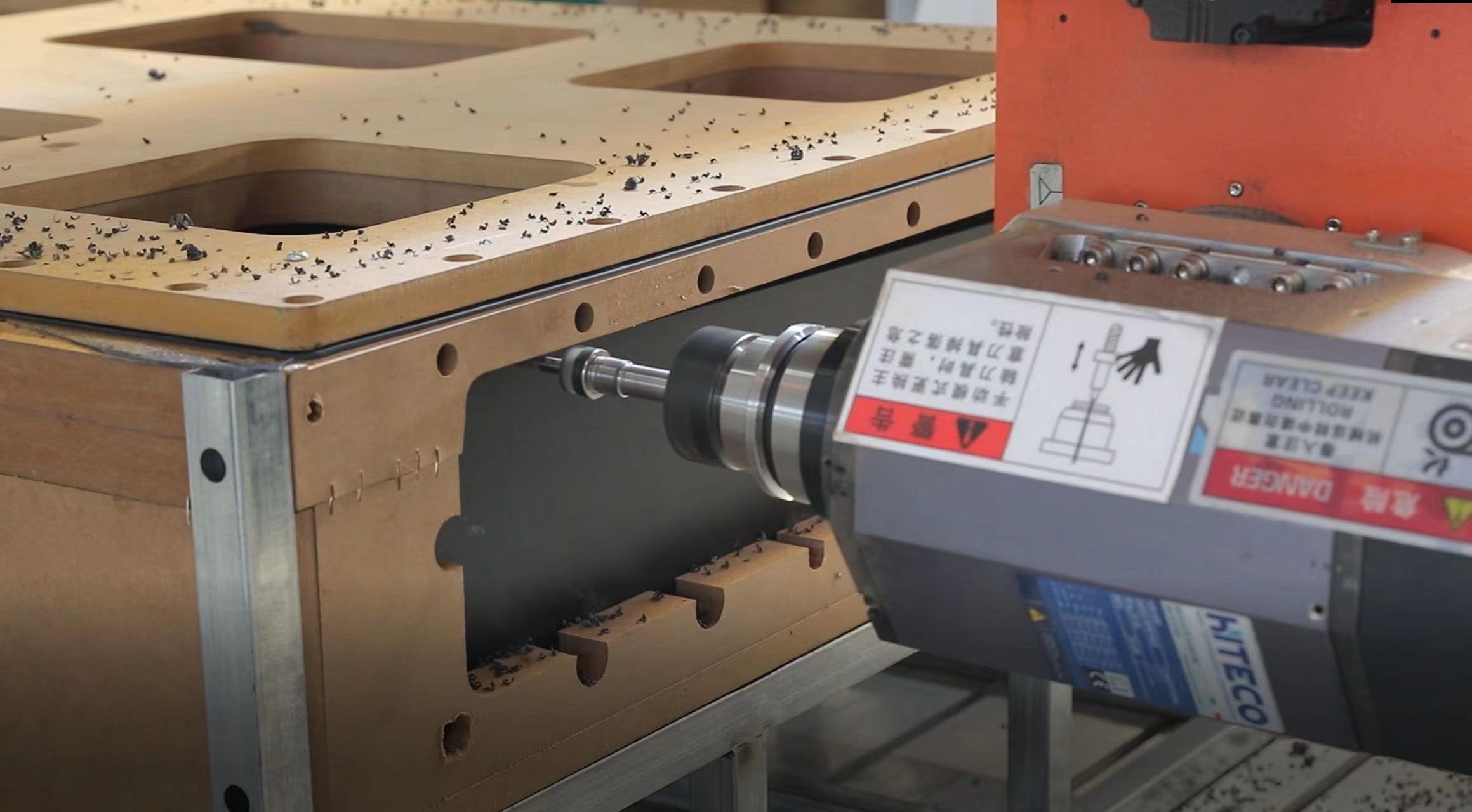

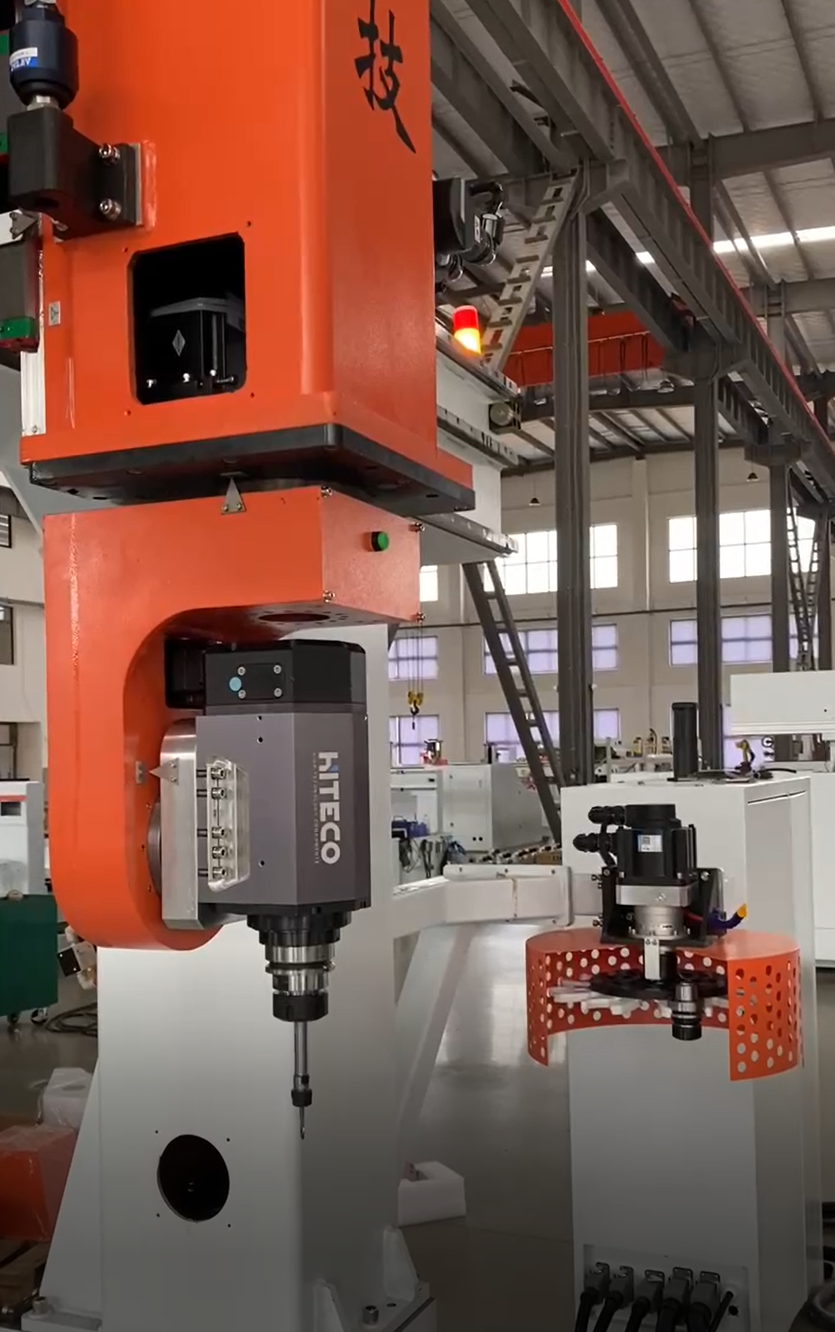

The Precision 5-Axis CNC Machining Centers are actually equipped along with a twin rotary milling scalp, including the 4th (C) and 5th (B) centers. This setup enables full 360-degree rotation, promoting the shaping of complex components, precise angled slices, and also effective multi-directional milling functions. These attributes are actually important for suppliers that call for a High-Performance 5-Axis CNC Router efficient in providing superior lead to asking for applications. The spindle, an essential part in these machines, is actually developed to sustain and also turn reducing tools at broadband, making certain accurate machining. Consumers may pick in between our proprietary spindles or even go for superior imported choices including Italy's Hiteco, which provide boosted functionalities for certain duties.

For fields needing specialized tools, we offer customized Thermoformed Plastic 5-Axis CNC Routers. These hubs are adapted to satisfy the particular manufacturing needs of fields like mold and mildew manufacturing, complex component handling, as well as thick piece thermoforming. The makers are created to process a range of products, including ABS, PVC, and various other non-metal materials, making sure versatility and preciseness all over various treatments. Also, our 5-Axis CNC Wood Carving Machines and 5-Axis CNC Trimming Machines are actually designed for activities that ask for in-depth craftsmanship as well as effective pruning functions, producing all of them important resources for experts in the woodworking market.

To even more enhance the preciseness as well as effectiveness of your production process, our hubs may be geared up along with CNC 5-Axis Rotary Tables for Enhanced Precision. These dining tables provide an added center of control, permitting elaborate describing as well as accurate multi-axis positioning. This function is actually specifically valuable for sectors where accuracy is very important. Matching this, our CNC Polishing Machines for Precision Finishing guarantee that the final product satisfies the highest requirements of surface top quality, important for treatments where an impeccable appearance is essential. These combined answers are made to sustain the absolute most tough production requirements, delivering outstanding end results all over a wide stable of components and also treatments.

he two workbenches run independently,one workbench is processing, the other workbench is loading and unloading;

The two workbenched run simultaneously, both workbenches can be worked as a big single table to process the big product.

Technical Parameters

No. | Items | Parameter | No. | Items | Parameter |

1 | Product name | Twin table 5-axis CNC Machining Center | 9 | Z axis maximum speed | 20m/min |

2 | model | RB-F6-2520-Z08 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

3 | X axis effective stroke | 2500mm | 11 | voltage | 380V |

4 | Y axis effective stroke | 2000mm | 12 | total power | 14.5KW |

5 | Z axis effective stroke | 820mm | 13 | spindle power | 5.5KW(customizable) |

6 | B-axis rotation angle | ±130° | 14 | Frequency | 50HZ |

7 | C-axis rotation angle | ±540° | 15 | weight | 4.1T |

8 | X/Y axis maximum speed | 35m/min | 16 | size | L3482*W3350*H3768mm |

Machine applicable to

Composite materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass fiber, carbon/carbon, etc.;

Plastics: ABS, PVC, PC, PP, PS, PE, PET, HDPE, PETG, Acrylic etc.;

Other non-metal material: high-density sponge, Styrofoam foam, wood, substitute wood, stone, plaster etc

Machine widely used in

Mold manufacturing, composite material processing, and thick sheet thermoforming processing in industries such as aerospace, rail transit, automotive interior and exterior, sporting goods, medical beauty, white goods, handicrafts, and sanitary ware.

Laser interferometer detection

CE Approved 5-axis cnc router

Cooperation Cases

Packing & Delivery