| Availability: | |

|---|---|

| Quantity: | |

RB-F5-1930-Z08

RBT

8465990000

5-axis CNC router is a sophisticated piece of machinery designed for high-precision machining across five different axes of movement, which includes three linear axes (X, Y, Z) and two rotational axes (typically A and B or C). Here are some key features that characterize a 5-axis CNC router:

1. Complex Part Machining: It can create complex parts with undercuts and angled surfaces that would be difficult or impossible to achieve with simpler machines.

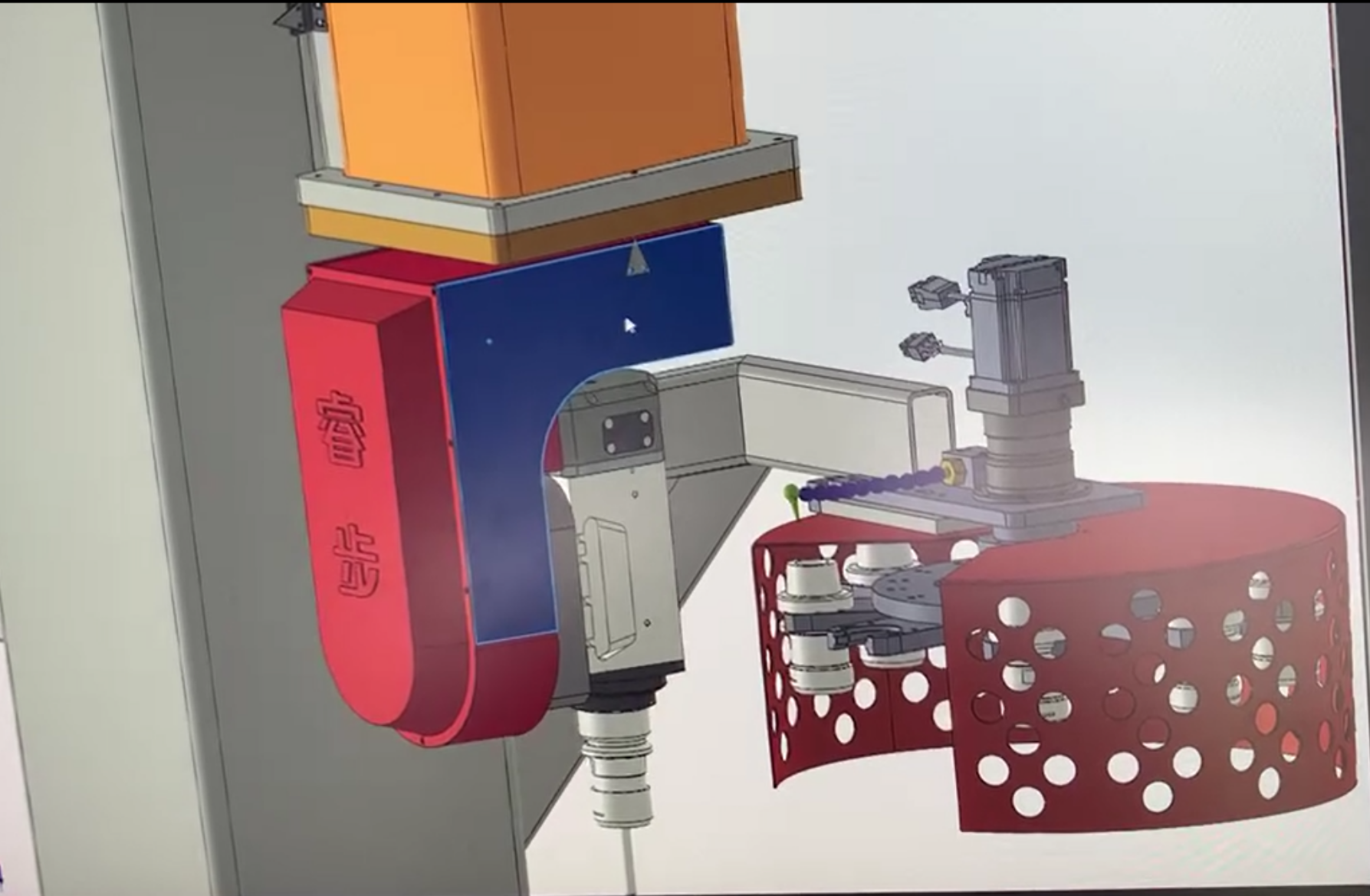

2. Simultaneous 5-Axis Machining: 5-axis routers can perform simultaneous movements along all five axes, which can lead to faster machining times and improved surface finishes.RBT independently developed and produced spindle or Germany/ Italy/ Korea imported spindle such as HSM, Hiteco, HSD for option. The tool magazine of a 5-axis CNC machine is a storage unit that holds multiple cutting tools, allowing for automatic tool changes during machining, enhancing efficiency and reducing setup time.

3. Tool Rotation: The rotational axes enable the tool to rotate around the workpiece, which is particularly useful for 3D carving and sculpting.

4. High Precision: equipped with high-precision transmission components such as Taiwan HIWIN roller type linear guides and TBI precision screw rod for the X/Y/Z axes to ensure accuracy in the final product.

5. Versatility: work with a wide range of materials, including but not limited to plastics, composites, metals, and wood.

6. Programming: adopts the SYNEC five-axis linkage CNC system,which has great advantages in terms of function, stability and after-sales service. General international standard G, M, T commands are compatible with NC programs generated by various CAD/CAM three-dimensional programming software such as UG and POWERMILL. Strong compatibility ensures barrier-free application.

7. Customization: machine size and specification can be customized based on customer product requirement.

8. Industry Applications: Suitable for industries that require high precision and complex geometries, such as aerospace, automotive, medical, and woodworking.

Technical Parameters

No. | Items | Parameter | No. | Items | Parameter |

1 | product name | FIVE-AXIS CNC MACHINING CENTER | 9 | Z axis maximum speed | 20m/min |

2 | model | RB-F5-1930-Z08 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

3 | X axis effective stroke | 1900mm | 11 | voltage | 380V |

4 | Y axis effective stroke | 3000mm | 12 | total power | 14.5KW |

5 | Z axis effective stroke | 800mm | 13 | spindle power | 5.5KW(customizable) |

6 | B-axis rotation angle | ±130° | 14 | Frequency | 50HZ |

7 | C-axis rotation angle | ±540° | 15 | weight | 3.5T |

8 | X/Y axis maximum speed | 35m/min | 16 | size | L5100*W2610*H3982mm |

Plastics: ABS, PVC, PC, PP, PS, PE, PET, HDPE, PETG, Acrylic etc.;

Composite materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass fiber, carbon/carbon, etc.;

Other material: high-density sponge, styrofoam foam, wood, stone, plaster,MDF, resin;

Other soft metal like aluminum/copper/ zinc, aluminum/ paper honeycomb etc.

What industries are five-axis CNC router suitable for?

Mold manufacturing, composite material processing, and thick sheet thermoforming processing in industries such as aerospace, rail transit, automotive interior and exterior,energy and buiulding, marine, packing, sporting goods, medical beauty, and sanitary ware.

Laser interferometer test and CE certificate

Sales network and strategic partners

RBT Exhibiton

Packing & Delivery