| Availability: | |

|---|---|

| Quantity: | |

RB-F10-4057-Z09

RBT

8465990000

Five Axis Twin Table Head CNC Machining Center

1.The SYNEC system provides advanced functionality that allows for complex machining operations. It can handle intricate tool paths and manage the simultaneous movement of the machine's five axes. It can achieve high levels of accuracy and repeatability, which is particularly important for applications that require tight tolerances.

2. Self-engineered RBT spindles, as well as a selection of high-quality imported options from renowned manufacturers such as HSM, Hiteco, and HSD from Germany, Italy, and Korea. These diverse choices cater to various performance requirements, ensuring you have access to the optimal spindle for your specific 5-axis CNC machining needs.

3. 8 Station Auto Tool Library Each Side: with 16 tool positions in total (8 on each side), the machine can store a wider variety of tools, which is beneficial for jobs that require multiple tool changes to complete different operations.The CNC machine can automatically change tools as needed during the machining process without operator intervention.It can minimize the time the machine spends idle, waiting for a human operator to change tools manually.

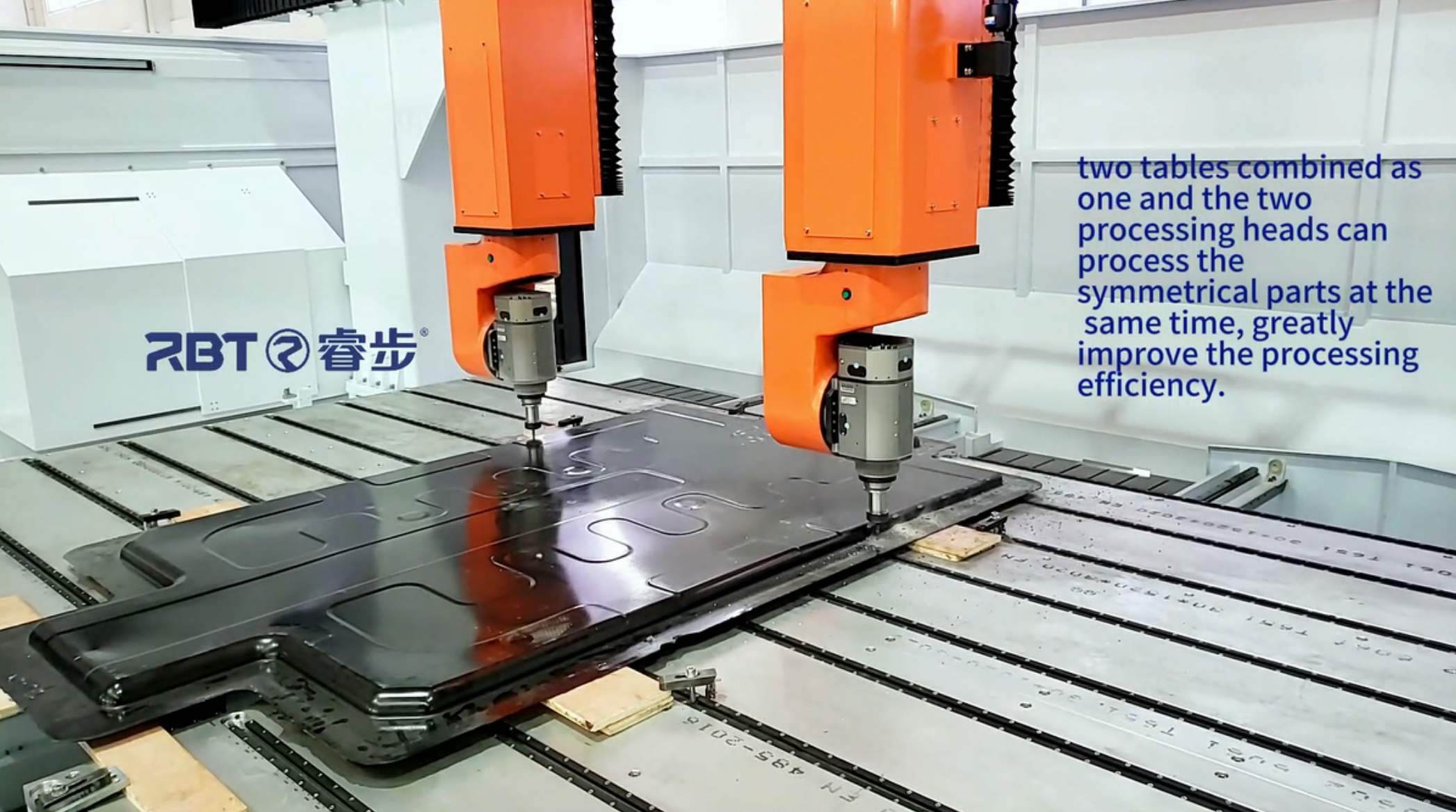

4. Two worktables can be combined into a group and interlocked with the two processing heads to process large workpieces, greatly improving the processing efficiency of symmetrical parts. And two worktables and heads can also work seperately, which is equivalent to having two five-axis machining centers performing processing operations.

5. A fully enclosed 5-axis CNC machine offers superior protection against dust and coolant, prolonging component life and ensuring consistent precision. It also dampens noise and vibrations, enhancing machining stability and operator comfort in the production environment.

6. RBT specializes in designing and manufacturing dust collection device for 5-axis CNC machining, ensuring efficient particulate extraction, improved workplace safety, and optimal machine performance in a clean, well-maintained environment.

Technical Parameters

No. | items | parameter | No. | items | parameter |

1 | product name | 5-axis CNC Machining Center with twin table & head | 9 | Z axis maximum speed | 20m/min |

2 | model | RB-F10-4057-Z09 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

3 | X axis effective stroke | 4000mm | 11 | voltage | 380V |

4 | Y axis effective stroke | 5700mm | 12 | total power | 19.15-31KW |

5 | Z axis effective stroke | 900mm | 13 | spindle power | 5.5-20KW(customizable) |

6 | B-axis rotation angle | ±120° | 14 | Frequency | 50HZ |

7 | C-axis rotation angle | ±540° | 15 | weight | 5-15T |

8 | X/Y axis maximum speed | 35m/min | 16 | size | 9000*6800*4250mm |

Application of 5 Axis CNC Machining Center

Structural parts CNC machining in industries such as aerospace, railway, automotive interior and exterior parts,energy and building, marine, packing, medical, patterns and moulds, sanitary ware.

Laser interferometer detection

CE Ceratificate

RBT Machine