| Availability: | |

|---|---|

| Quantity: | |

RB-H5-2540-Z11

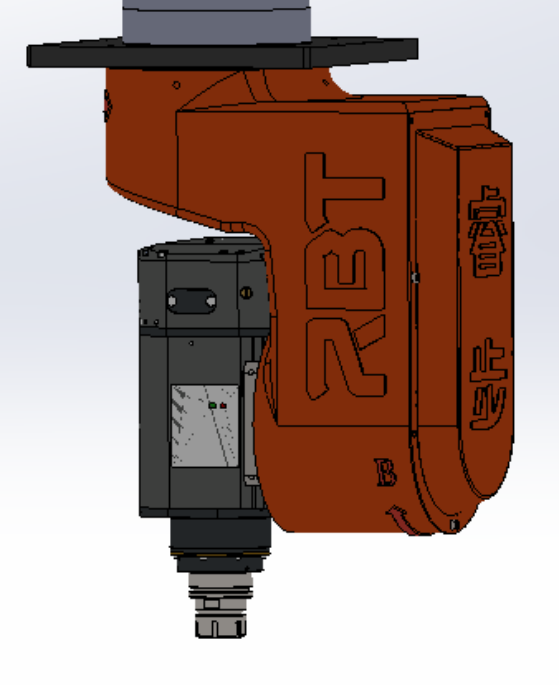

RBT

8465990000

1. Adjustable Heavy-Duty Spindle

A 5-axis machining spindle for aluminum mold processing is a high-precision, rigid tool that enables complex, multi-directional cutting. It's designed for smooth, efficient machining of intricate molds with minimal material wastage, ensuring accuracy and surface finish. We have RBT brand or Italy/Germany imported spindle for option based on customer needs.

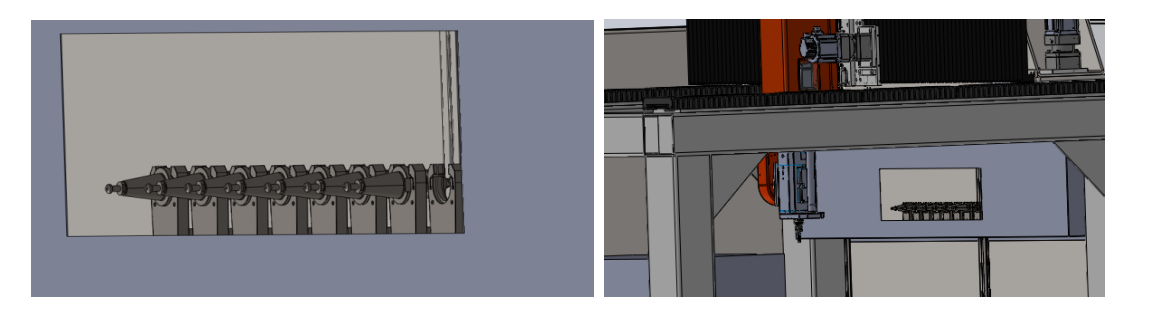

2. Automatic Tool Changing (ATC) for tool quick replacement

With 8-12 clamp tool magazine. The self-actuating tool exchange and precision alignment ensures seamless, unattended machining of the workpiece from initiation to completion in a single fixture setup.

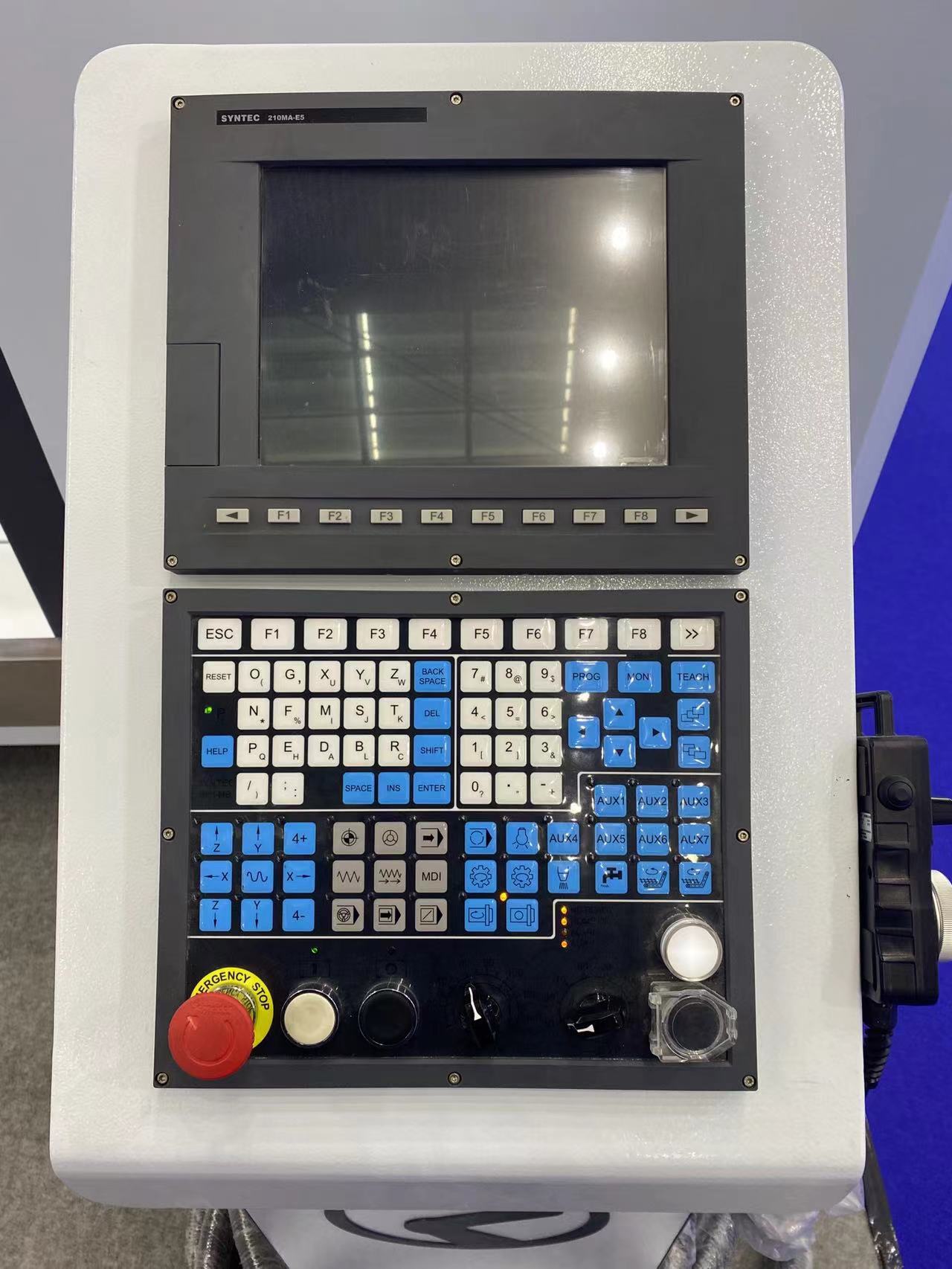

3.Versatile CNC Control Systems for 5-Axis Machining Excellence

The Taiwan Syntec CNC system for 5-axis CNC machining is a state-of-the-art control solution renowned for its user-friendly interface and advanced capabilities. It seamlessly integrates with multi-axis machines, enabling complex part programming and tool path optimization. The system offers high-speed processing, precise motion control, and real-time feedback for enhanced machining accuracy. With robust software support for CAD/CAM integration, the Syntec system boosts efficiency and productivity in 5-axis machining environments, catering to a wide range of applications from mold making to aerospace components. Other cnc system such as Mitsubishi, Siemens, and Fanuc is also workable.

4. Robust Welded Steel Bed with Reinforced Ribs for Unmatched Machining Stability

The welded steel bed is adopted, the bed is solid, and the key parts are added with ribbed plates. And the cast iron T-slot work surface has good rigidity and stability.

5. The water circulation working table satisfies the flushable machining of aluminum moulds.

6. Transmission parts

X / Y / Z adopts Taiwan HIWIN roller linear guide, double row and six row sliders, with large bearing capacity, suitable for heavy cutting.

X /Y / Z adopts Taiwan TBI precision grinding rack and pinion, with small backlash, high precision and stable operation;

X /Y axis adopts Japanese Shimpo reducer;

The C/B axis adopts the Japanese Sumitomo Precision hollow reducer.

Technical Parameters

Application of 5 Axis CNC Machining Center

The CNC Mills is crafted for swift machining of molds and patterns from materials such as Styrofoam, wood, resin, plaster, aluminum, etc. These 5 axis cnc machining centers are designed to operate at a speed much quicker than that of conventional metalworking CNC Mills, offering a high-speed alternative for material processing.

CE Approved 5 Axis CNC Machining Center

Featured Clients