| Availability: | |

|---|---|

| Quantity: | |

RB-H5-1915-Z11

RBT

8465990000

The Syntec CNC system from Taiwan is a user-friendly, advanced control system designed for 5 axis CNC machining centers, offering high-speed processing, precision machining, and comprehensive programming support for complex part production. This system is highly versatile, making it ideal for a range of applications, including mold making machines and wood milling machines.

A two CNC continuous rotary milling head for a 5-axis CNC machining center features the 4th (C) and 5th (B) axes, enabling full 360-degree rotation for complex part shaping, precise angled cuts, and efficient multi-directional milling operations. This capability is particularly beneficial in composite 5 axis CNC routers, where precision and flexibility are crucial for machining composite materials.

The spindle, a precision component that supports and rotates the cutting tool, is essential for high-speed, accurate machining. We offer both our own brand spindles for reliable performance and premium imported options like Italy's Hiteco for enhanced capabilities. For specialized needs, we provide customized 5 axis CNC routers that cater to specific applications, such as thermoformed plastic 5 axis CNC routers and 5 axis CNC routers for composites.

The entire product's multi-face processing can be accomplished in a single clamping, ensuring high precision, efficient operations, and accurate positioning. For optimal material handling, our vacuum 5 axis CNC routers provide exceptional stability and control, crucial for both standard and specialized tasks.

We specialize in designing and fabricating custom fixtures tailored for one-time 5-axis CNC machining operations, ensuring precise and efficient part production with a focus on accuracy and repeatability. Our offerings include automatic 5 axis CNC routers, equipped with advanced features for seamless automation and enhanced productivity.

The 5-axis CNC router's tool magazine stores an array of cutting tools, facilitating seamless and automated tool transitions throughout the machining process, thereby optimizing workflow and minimizing downtime. Our dual workbench setups offer flexibility: one workbench can process while the other is loading and unloading, or both can work simultaneously as a large single table to handle bigger projects efficiently.

Technical Parameters

5 Axis CNC Machining Center Processing material

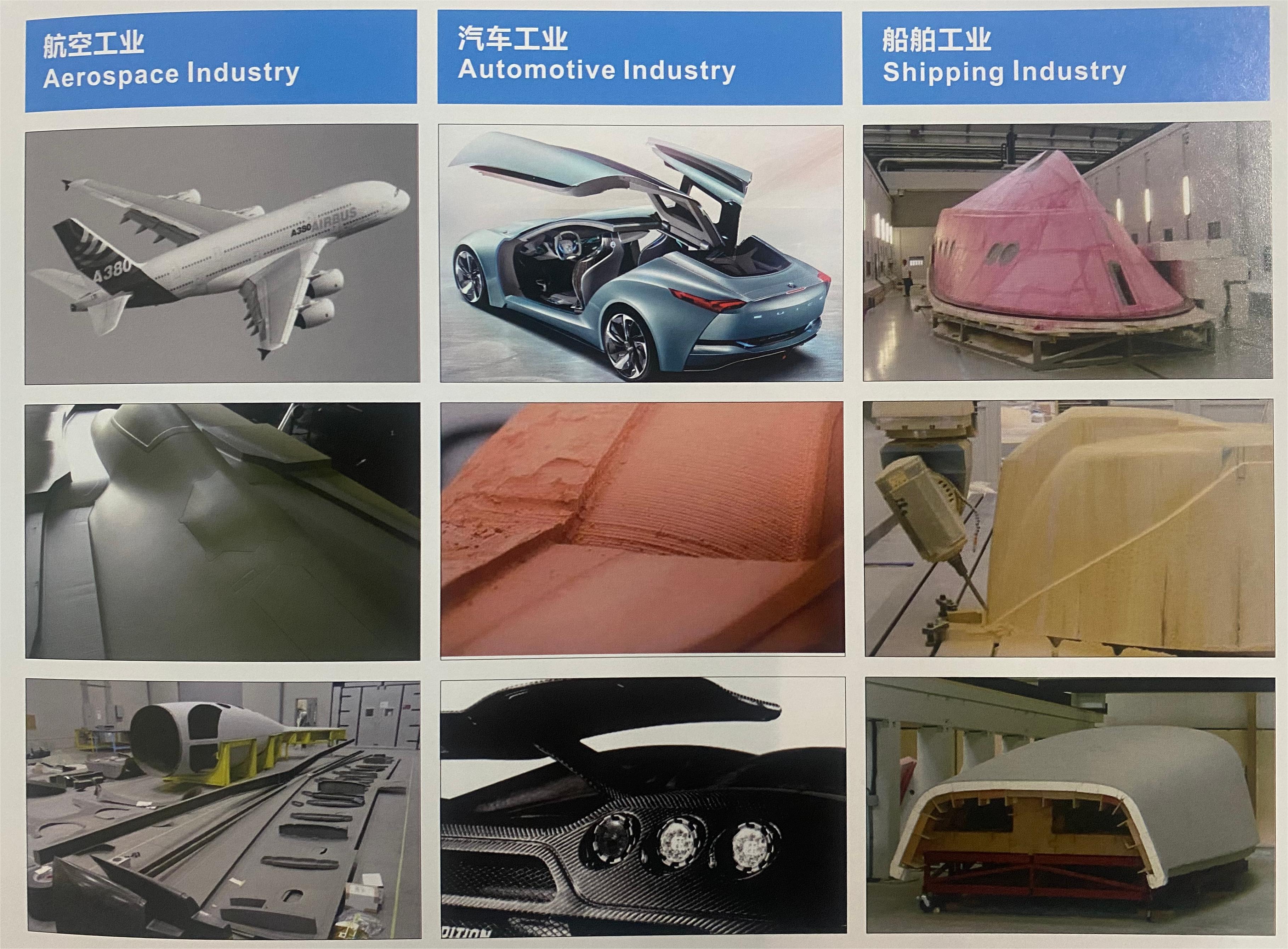

5 Axis CNC Machining Center Application Industry

Laser interferometer test accuracy

CE Apporved 5-axis CNC Machining Center