| Availability: | |

|---|---|

| Quantity: | |

RB-H6-3626-Z12

RBT

8465990000

The implementation of the SYNEC CNC system with five-axis linkage provides significant advantages in terms of functionality, stability, and after-sales support. It supports five-axis machining and offers user-friendly operation and application features. This makes it an excellent choice for a composite 5 axis cnc machining center or a composite 5 axis cnc router, ensuring high performance and reliability. The composite 5 axis CNC machining center can handle complex tasks with precision, making it suitable for various industrial applications.

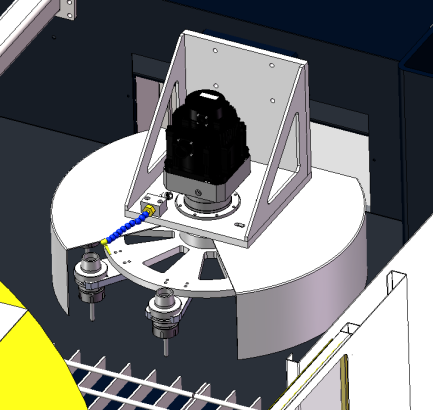

2. The milling head possesses two CNC rotary coordinates that can continuously rotate: the 4th (C) axis and the 5th (B) axis. This allows for coordinated processing, including cutting, punching, and trimming. The entire product can be processed on multiple faces in a single clamping, ensuring high precision, efficient operations, and accurate positioning. Self-engineered RBT cnc spindles, as well as a selection of high-quality imported options from renowned manufacturers such as HSM, Hiteco, and HSD from Germany, Italy, and Korea. These diverse choices cater to various performance requirements, ensuring you have access to the optimal spindle for your specific composite 5 axis CNC machine or composite 5 axis CNC machine needs. The RBT cnc system enhances the machine's versatility and operational efficiency.

3. The tool magazine of a composite 5 axis CNC machine is a storage unit that holds multiple cutting tools, allowing for automatic tool changes during machining, enhancing efficiency and reducing setup time. This feature is crucial for the 5 Axis CNC Machining center for glass fiber and the 5 Axis CNC Machining center for carbon fiber, as it ensures smooth and continuous operations. The composite 5 axis cnc machining center is designed to handle these materials with high precision.

4.The two workbenches operate independently, with one workbench handling processing tasks while the other workbench handles loading and unloading. The two workbenches operate simultaneously, functioning as a large single table to process the big product, which is a significant advantage for composite 5 axis cnc machining centers. This dual functionality maximizes productivity and minimizes downtime in composite 5 axis cnc machining centers.

5.The truss-type double worktable and the protective room structure meet the safety protection and debris prevention during production. The floor drain dust collection device cooperates with the high-performance dust collector to collect external processing debris. This setup is ideal for a composite 5 axis cnc router, ensuring a clean and safe working environment. The composite 5 axis cnc router is engineered to handle complex machining tasks efficiently while maintaining a safe and clean workspace.

Technical Parameter

Machine speed | Fast movement speed /G00 | X | 35m/min |

Y | 35m/min | ||

Z | 20m/min | ||

Processing speed/G01 | 0~12m/min | ||

Spindle | Power | 20KW | |

Cooling | Water cooling | ||

RPM | 24000RPM | ||

Working travel | X axis | 3600mm | |

Y axis | 2600mm | ||

Z axis | 1200mm | ||

C axis | ±540° | ||

B axis | ±120° | ||

Positioning Accuracy (300mm) | X、Y axis | ±0.05mm | |

Z axis | ±0.05mm | ||

B、C axis | 30 arc seconds | ||

Repeated Positioning Accuracy (300mm) | X、Y axis | ±0.05mm | |

Z axis | ±0.05mm | ||

B、C axis | 15 arc seconds | ||

Platform size | L2020mm * W1560mm | ||

Cutting suction port | 4-∅250mm | ||

Total power | ≈33.8KW | ||

Input voltage | AC380V±10% | ||

Tool handle | HSK63A | ||

Control system | SYNTEC | ||

Dimension and weight | 6800*8000*5000mm, 15000kg | ||

5 Axis CNC Machining Center for Plastic and Composite

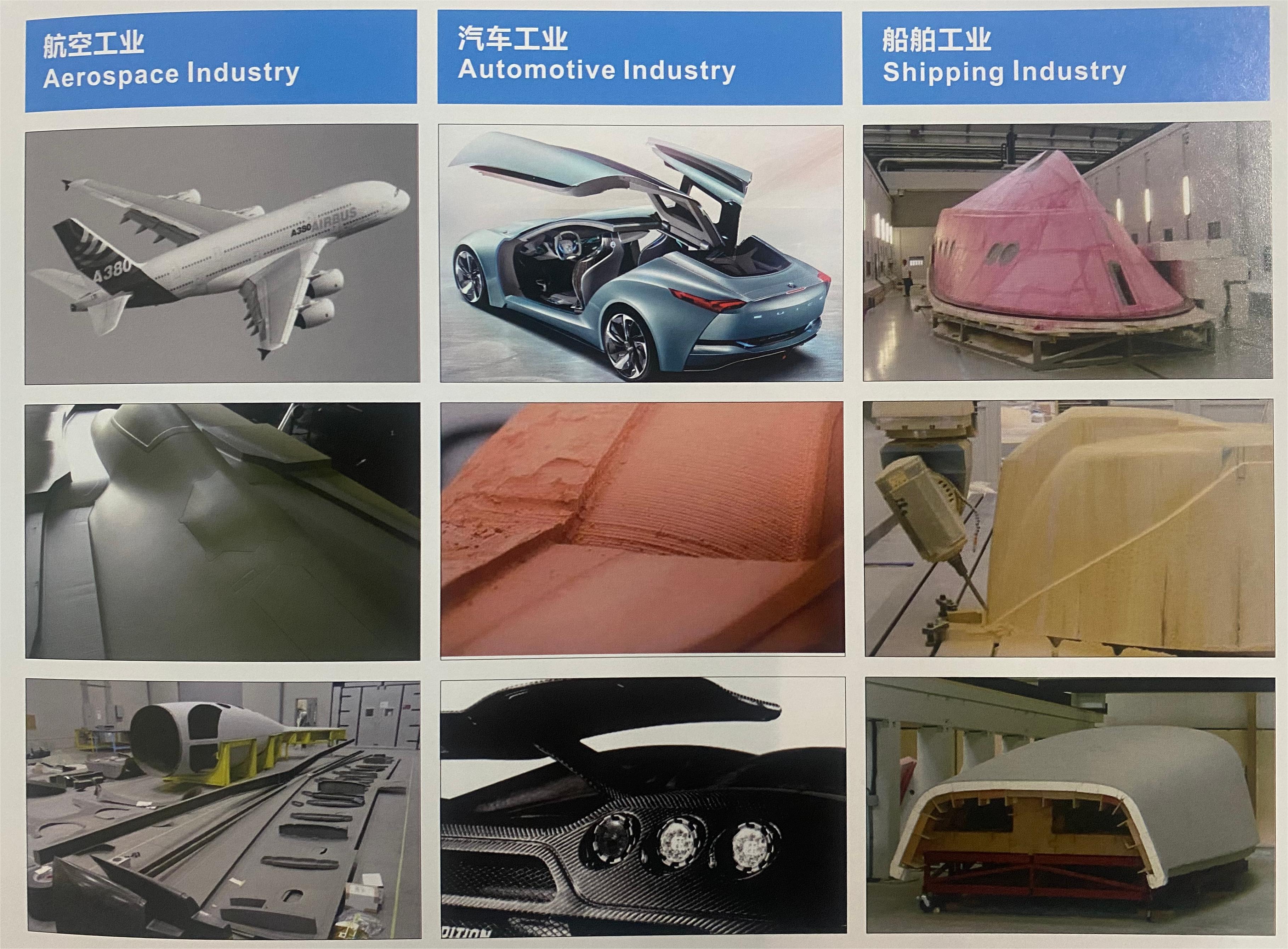

5 Axis CNC Machining Center for Aerospace, Automotive and Shipping

How to make sure the accuracy of a 5 axis cnc machining center?

The assembly process is strictly in accordance with the standards of CNC machine tools, and laser trackers, British Renishaw ballbars, etc. are used for machine inspection and error compensation to ensure assembly accuracy.

BYD & BENZ & RBT 5 Axis CNC Machining Center

RBT 5-axis CNC machine precisely processes BYD and Benz vehicle battery covers, ensuring high-precision contours and complex geometries that meet stringent automotive standards for quality and durability.