| Availability: | |

|---|---|

| Quantity: | |

RB-F5-1930-Z08

RBT

8465990000

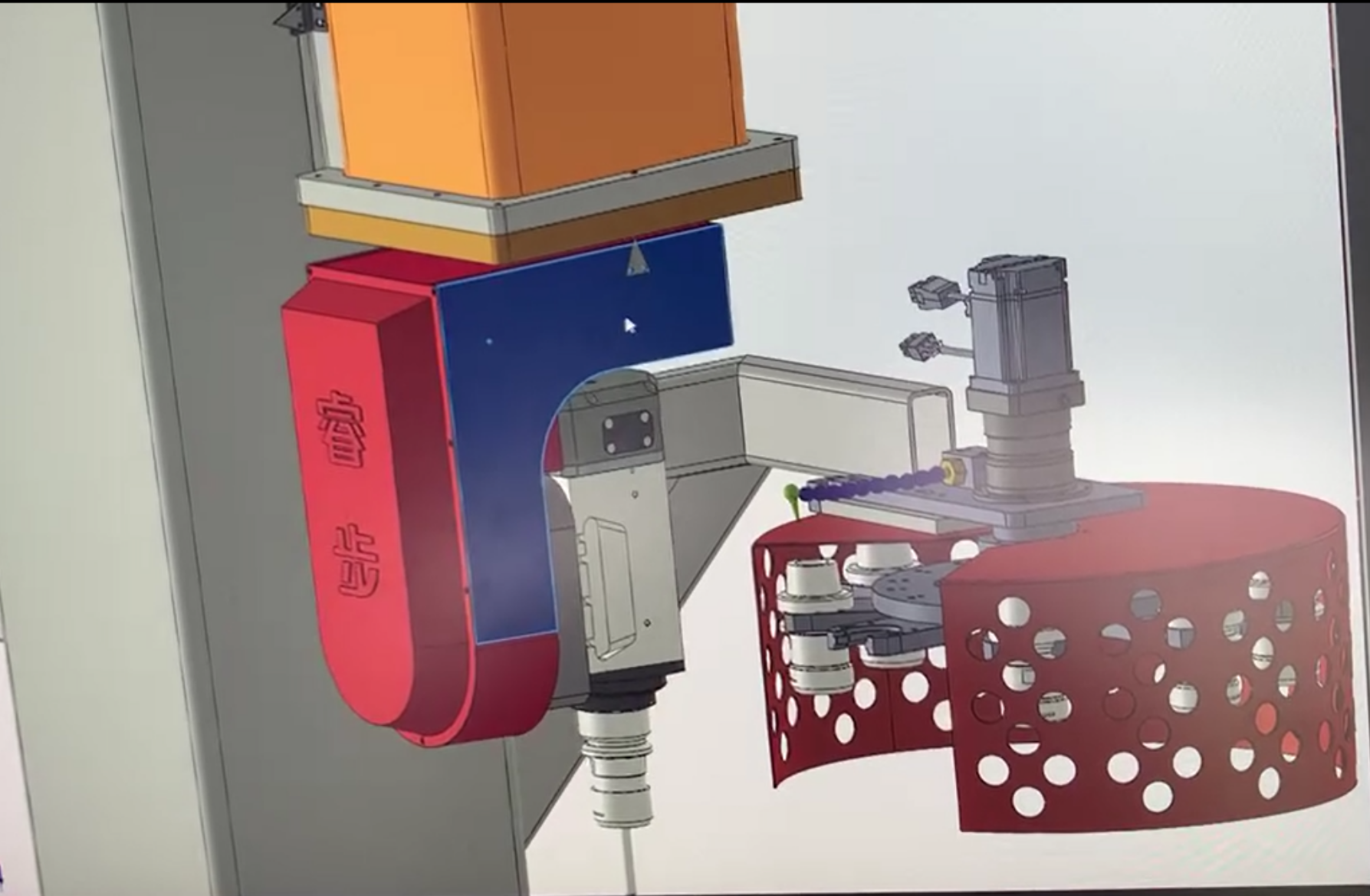

The B/C axes rotate continuously, supporting high-precision real-time interpolation, making it ideal for freeform surface machining and complex shape milling.

This 5 axis cnc router is engineered for applications that demand maximum accuracy and flexibility.

The multi-angle cutting capability allows operations to be completed in a single clamping, improving efficiency and minimizing cumulative errors.

A perfect solution for industries requiring cnc milling center light alloy processing and cnc milling center composite machining.

The X/Y/Z axes feature Taiwanese HIWIN high-precision linear guides, ensuring smooth and stable motion control.

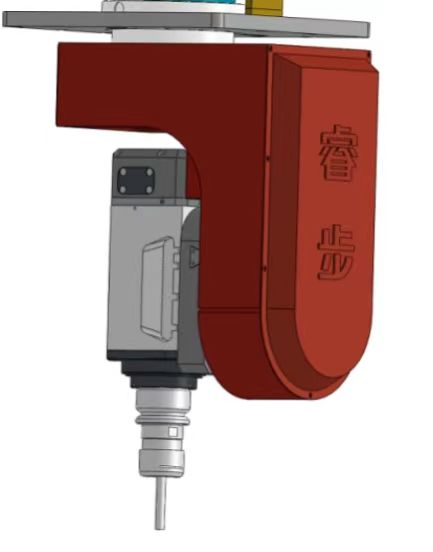

The C/B axis utilizes a high-precision Sumitomo (Japan) hollow reducer, enhancing rotational accuracy and durability.

Automatic Tool Change System (ATC): Supports multiple tool magazine configurations, reducing tool change time and improving production efficiency.

RTCP Function (Rotating Tool Center Point Compensation): Ensures accurate machining paths, particularly for curved and contoured surfaces.

Efficient Dust Collection System (Optional): Enhances the working environment and extends the equipment's lifespan.

Laser interferometer precision testing guarantees that movement precision meets stringent international standards.

Complies with CE certification to ensure safety and operational reliability.

✔ Best 5 axis CNC router with cutting-edge five-axis technology for complex 3D machining needs.

✔ Advanced intelligent control system to enhance operational convenience and production efficiency.

✔ Versatile machining center capable of handling both light alloys and composites with high precision.

✔ Global quality compliance with strict testing and certification, ensuring long-term stability and reliability.

The RBT 5-axis CNC machining centre supports high-precision machining of a wide range of materials, making it an ideal solution for processing:

✔ Composite materials (carbon fiber, glass fiber, aramid fiber, etc.) – Ideal for cnc milling center composite applications.

✔ Thermoformed plastics (PMMA, ABS, PC, PVC).

✔ Light alloys and aluminum – Suitable for machining centre light alloys and cnc milling center light alloy processing.

✔ Wood, MDF, plywood, and foam – Excellent for complex contour machining.

Technical Parameters of 5 axis cnc machining center

No. | Items | Parameter | No. | Items | Parameter |

1 | product name | FIVE-AXIS CNC MACHINING CENTER | 9 | Z axis maximum speed | 20m/min |

2 | model | RB-F5-1930-Z08 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

3 | X axis effective stroke | 1900mm | 11 | voltage | 380V |

4 | Y axis effective stroke | 3000mm | 12 | total power | 14.5KW |

5 | Z axis effective stroke | 800mm | 13 | spindle power | 5.5KW(customizable) |

6 | B-axis rotation angle | ±130° | 14 | Frequency | 50HZ |

7 | C-axis rotation angle | ±540° | 15 | weight | 3.5T |

8 | X/Y axis maximum speed | 35m/min | 16 | size | L5100*W2610*H3982mm |

✔ Aerospace: Aircraft components, carbon fiber structural parts.

✔ Automotive manufacturing: Body molds, instrument panels, and interior parts.

✔ Energy and construction: Wind turbine blades, architectural decorative elements.

✔ Marine and shipbuilding: Yacht interiors, structural components.

✔ Medical equipment: Surgical models, medical device housings.

✔ Packaging industry: Foam molds, plastic packaging dies.

✔ Rail transit: High-speed rail and subway component processing.

✔ Mold manufacturing: Casting molds, composite material molds.

Laser interferometer accuracy test and CE certificate

Representative customers

RBT Exhibiton

Packing & Delivery