| Availability: | |

|---|---|

| Quantity: | |

RB-F6-QGJ-0810-Z07

RBT

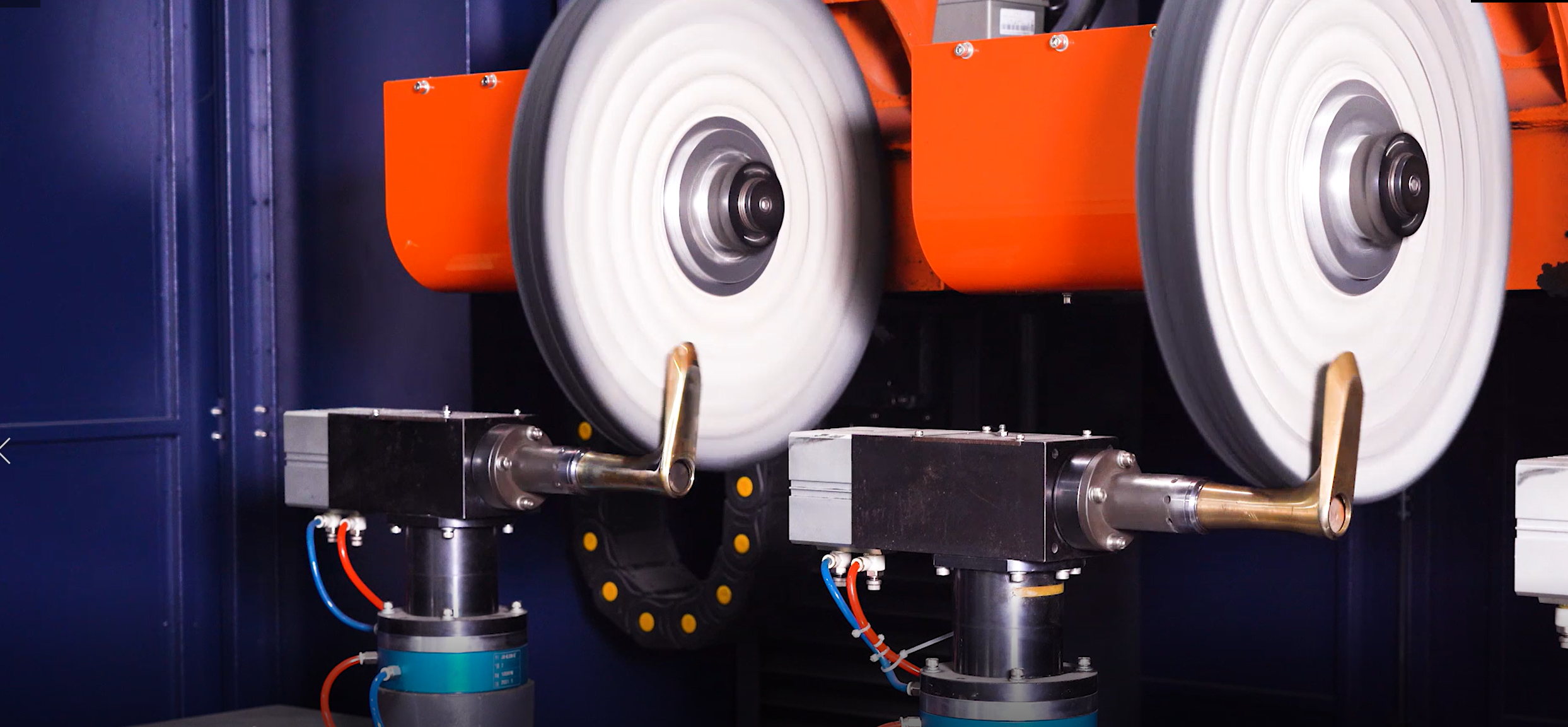

Machine Function

4 station CNC polishing & buffing machine suitable for the polishing,buffing, mirror polishing, clearing of the bathroom ware faucet, hardware, casting pieces, car accessory, lock, door knob etc. Applicable to brass, zinc alloy, stainless steel, aluminum faucet or other hardware.

Machine Details

Six-Axis, Four-Station Operation: This CNC cleaning machine offers 6 degrees of freedom with four stations operating synchronously, suitable for product cleaning in sanitary ware faucet, hardware, auto parts and door handles.

Advanced Motion Control System: Equipped with HCNC system that ensures stable performance and high precision in control.

Programming Method: The machine uses a teach pendant for manual mode programming, simulating manual polishing to record and follow the path automatically.

Automatic Compensation for Clearing Wheel: The wheel is automatically compensated to ensure the accuracy of the cleaning process.

Waxing Setting: Capable of selecting between solid or liquid wax based on product characteristics, with adjustable wax amount and frequency.

Digital Control: Allows for the storage of multiple programs that can be recalled at any time.

Technical Parameters

No. | Product | 4 Station CNC Buffing Machine | No. | Brand | RBT |

1 | Model | RB-F6-QGJ-0810-Z07 | 9 | X axis travel | 850mm |

2 | Total power | 39.3KW | 10 | Y axis travel | 920mm |

3 | Voltage | 380V | 11 | Z axis travel | 600mm |

4 | Max size of polishing wheel | 600mm | 12 | U axis travel | ±90° |

5 | Min size of polishing wheel | 400mm | 13 | V axis travel | ±720° |

6 | Number of polishing stations | 4 | 14 | W axis travel | ±720° |

7 | Polishing motor power | 5.5KW | 15 | Max processing workpiece length | 330mm |

8 | Size | L4500*W3390*H2590MM | 16 | Weight | 8T |

Machine Accuracy Control by laser interferometer

Cooperation cases

Company Profile: