Views: 0 Author: Site Editor Publish Time: 2025-03-13 Origin: Site

CNC (Computer Numerical Control) machining has revolutionized modern manufacturing. It’s used across industries like automotive, aerospace, and medical. Understanding the difference between 5-axis and 6-axis CNC machines is crucial for selecting the right equipment. These machines are known for their precision and versatility.

In this article, we’ll break down the key differences between 5-axis and 6-axis CNC machines. You’ll learn which machine suits specific applications and how to choose the best option for your needs.

CNC (Computer Numerical Control) machining is a highly efficient manufacturing process that uses pre-programmed computer software to control machine tools. This process enables precise cutting, drilling, and shaping of materials like metals, plastics, and wood. It has widespread applications in industries like automotive, aerospace, medical devices, and consumer electronics.

CNC machining relies heavily on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to create and implement designs. CAD is used to design parts and generate 3D models, while CAM software translates these designs into machine instructions. These instructions, known as G-code, tell the CNC machine exactly how to move and cut.

There are various types of CNC machines, each designed for specific tasks:

2-axis CNC machines: Move in two directions—forward/backward and left/right. They are suitable for simple tasks like drilling holes or engraving.

3-axis CNC machines: Add vertical movement, allowing for more complex cuts such as milling.

4-axis CNC machines: Include one more rotational axis, enabling the machine to cut around a part’s surface.

5-axis CNC machines: Add two more rotational axes, allowing for even more intricate cutting and angles.

6-axis CNC machines: These have an additional axis for even more precise and complex operations, ideal for manufacturing highly detailed and complex parts.

In modern manufacturing, accuracy, speed, and automation are key factors that improve efficiency and reduce human error. CNC machines excel in all these areas:

Accuracy: CNC machines provide consistent, high-precision cuts.

Speed: With automated programming, CNC machines can perform tasks much faster than manual machines.

Automation: CNC machines reduce the need for manual labor, enabling continuous production with minimal intervention.

5-axis CNC machine moves the cutting tool along five axes—three linear (X, Y, Z) and two rotational (A, B). This allows it to perform precise cuts from multiple angles, making it ideal for creating complex parts like engine components, molds, and medical devices.

6-axis CNC machine builds on the 5-axis by adding an extra rotational axis, usually the C-axis, which rotates around the workpiece. This additional axis allows for even greater flexibility and precision, making it suitable for intricate parts in industries like aerospace, automotive, and medical.

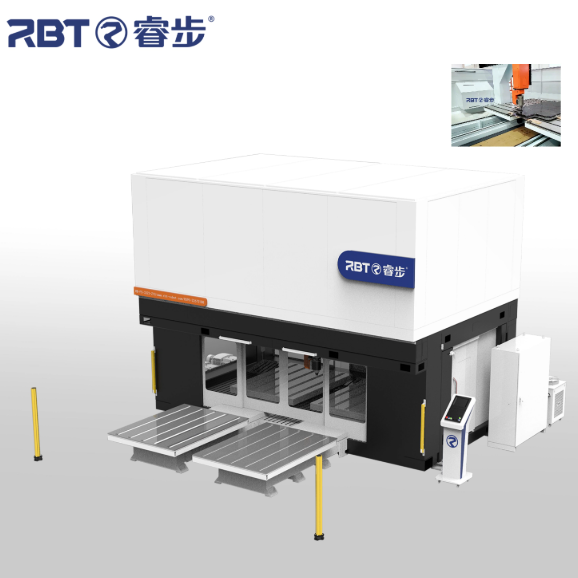

At Fujian RBT Intelligent Equipment Co., Ltd., we specialize in providing top-of-the-line CNC machining solutions. With over 24 years of experience, we deliver 5-axis and 6-axis CNC machines that meet the highest quality standards. Whether you're in aerospace, automotive, or medical industries, our advanced machines are designed to enhance your production capabilities, ensuring precision, efficiency, and speed. Contact us today to learn more about how we can support your manufacturing needs.

5-Axis CNC Machines: These machines move the cutting tool along three linear axes (X, Y, Z) and two rotational axes (A, B). They allow the tool to reach different angles and create more complex parts than traditional machines.

6-Axis CNC Machines: In addition to the 5 axes of movement, 6-axis CNC machines include a C-axis, which adds another rotational movement. This extra axis provides even more flexibility, allowing the machine to reach areas that 5-axis machines can't access as easily.

This added axis makes 6-axis machines much more versatile, enabling them to perform detailed cuts from multiple angles in a single setup.

5-Axis: While 5-axis machines are highly precise, they can sometimes struggle with extremely complex geometries that require more rotational movement.

6-Axis: The additional C-axis in 6-axis CNC machines greatly improves precision by allowing for better control and access to every part of the workpiece. This makes 6-axis machines ideal for parts that require high precision, such as aerospace components or medical implants.

In situations where extreme accuracy is critical, such as turbine blades or custom medical devices, a 6-axis machine offers a clear advantage.

5-Axis: Although 5-axis CNC machines are efficient and fast, they may require more time to reposition the workpiece or tool to complete certain cuts.

6-Axis: The 6-axis CNC machine reduces cycle times by completing more movements in a single pass. This results in faster production, especially for parts with intricate geometries.

In industries where high demand and fast production are crucial, such as automotive and aerospace, 6-axis machines provide a significant speed advantage.

5-Axis: Generally more affordable than 6-axis CNC machines, making them suitable for less complex parts and applications.

6-Axis: The extra rotational axis and additional complexity make 6-axis CNC machines more expensive, both in terms of purchase price and maintenance.

However, the increased capabilities of 6-axis machines may justify the higher cost for businesses that require precision and speed for complex parts.

5-Axis: Perfect for parts that require a high level of precision but have less complex geometries. Common uses include engine blocks, brackets, and components that require detailed cutting along multiple axes.

6-Axis: 6-axis CNC machines excel at handling highly complex parts, such as turbine blades, medical implants, and molds that require intricate angles and detailed cuts. The extra axis allows for more complex movements, making it ideal for custom designs and parts with tight tolerances.

For parts like turbine blades or medical implants, the flexibility and precision of 6-axis CNC machining are essential.

Parts with Complex Cuts but Simple Designs: If you need detailed cuts but the shapes are not overly intricate, a 5-axis CNC machine is a great choice. It can handle many angles and cuts, but it's more affordable and simpler than a 6-axis machine.

Industries Requiring Precision and Reduced Setup Time: In industries like automotive and consumer electronics, where precision is important but the designs are less complex, 5-axis CNC machines are ideal. They offer a good balance of speed, accuracy, and efficiency.

Highly Complex Parts: For parts that require detailed cuts from multiple angles, such as turbine blades or medical implants, a 6-axis CNC machine is better. It allows for more flexibility and higher precision.

Aerospace and Medical Industries: These industries often require parts with complex geometries. 6-axis CNC machines can easily handle tasks that demand high versatility and precision, such as aerospace components or custom prosthetics.

Budget Constraints and Production Needs: If you are on a tight budget and don’t need extreme precision, a 5-axis CNC machine might be a better fit. However, if precision and speed are essential, investing in a 6-axis machine could be worthwhile.

Volume of Parts Required and Complexity: For higher volumes of simpler parts, a 5-axis machine works well. But for smaller batches of highly intricate parts, 6-axis CNC machining is more efficient in the long run.

Long-Term Investment: A 6-axis CNC machine is a significant investment but offers flexibility for future projects. If your business plans to handle increasingly complex parts, it could provide higher returns in the future.

To get the most out of your 5-axis or 6-axis CNC machine, proper setup is crucial. Here are some tips to ensure precise cuts and efficient operations:

Check Calibration: Regularly calibrate the machine to maintain accuracy.

Tool Selection: Choose the right cutting tools for the material and the desired cut.

Optimize Cutting Paths: Use CAM software to design efficient toolpaths that minimize cutting time while maintaining precision.

CAM software integration is key. It translates CAD designs into machine instructions (G-code), allowing for seamless operation. Good software helps maximize the capabilities of both 5-axis and 6-axis machines, ensuring that the machine operates smoothly and efficiently.

Different materials behave differently during machining, so it's important to select the right one for your project:

Metals: Steel, aluminum, and titanium are common materials for CNC machining. These materials require higher precision, and 6-axis machines are often better suited for complex parts.

Plastics and Composites: These materials are easier to machine, and both 5-axis and 6-axis CNC machines can handle them well. However, choosing the right type of plastic or composite can affect machining time and precision.

Alloys: Alloys are often used in industries like aerospace. They may require specific tools and settings to prevent wear and tear on the machine.

The material choice directly impacts machining time and precision. Harder materials may require slower speeds, while softer materials allow faster cuts.

Regular maintenance is crucial for keeping your CNC machines running smoothly:

Routine Checks: Perform routine inspections of the machine’s moving parts, tool holders, and spindle.

Lubrication: Regularly lubricate the machine to avoid wear and tear on critical components.

Software Updates: Keep your CNC machine’s software updated to ensure it runs efficiently.

Preventative maintenance can help avoid costly repairs and downtime. By scheduling regular checkups and following the manufacturer’s guidelines, you can extend the lifespan of your 5-axis and 6-axis CNC machines.

In this article, we explored the key differences between 5-axis and 6-axis CNC machines. 5-axis CNC is ideal for less complex parts, offering efficiency and precision, while 6-axis CNC excels in creating highly complex, detailed parts. Each machine type suits different industries based on production needs. CNC technology continues to revolutionize manufacturing. For more information or a demo, feel free to contact RBT and explore the right CNC machine for your business.

A: A 5-axis CNC machine is more cost-effective and suitable for less complex parts, while a 6-axis machine offers more precision and flexibility for highly intricate parts.

A: While 5-axis CNC machines are highly precise, 6-axis machines are often better suited for complex aerospace components that require more detailed cuts and higher precision.

A: 6-axis CNC machines provide greater flexibility, faster production, and the ability to produce more complex, detailed parts with higher precision, ideal for industries like aerospace and medical.

A: Yes, operating a 6-axis CNC machine requires specialized training due to its complexity and advanced capabilities. Proper training ensures safety and maximizes machine efficiency.