Views: 0 Author: Site Editor Publish Time: 2024-12-18 Origin: Site

When it comes to high-precision manufacturing, few tools are as indispensable as the 5 Axis CNC Machining Center. These machines can handle complex geometries and multi-directional cutting with unmatched accuracy, making them a must-have in industries like aerospace, automotive, medical, and electronics. However, choosing the best 5 Axis CNC Machining Service for your project requires careful consideration. This article will guide you through the process of selecting the right service provider, focusing on factors such as capabilities, expertise, quality assurance, and cost-effectiveness.

A 5 Axis CNC Machining Service is a machining service that uses a 5 Axis CNC Machining Center to manufacture parts by manipulating the material in five different axes. These axes typically include the traditional X, Y, and Z axes, along with two rotational axes (often labeled A and B) that allow for the tilting of the workpiece. This added degree of freedom enables the production of complex parts with high precision and a superior surface finish.

Given the advanced nature of 5 Axis machining, it is most commonly used for producing intricate parts used in industries like aerospace, automotive, medical devices, and high-precision manufacturing. It is especially beneficial for machining parts made from hard materials such as metals, composites, and glass.

Using a 5 Axis CNC Machining Service offers several advantages over traditional 3-axis machining services. Some of these benefits include:

Increased precision and accuracy: 5 Axis CNC machining provides superior precision, particularly when dealing with intricate designs and tight tolerances.

Reduced setup time: Unlike 3 Axis machines, which require the repositioning of the workpiece multiple times, 5 Axis CNC Machining Centers can complete the task without such interruptions, reducing overall machining time.

Ability to handle complex geometries: With the capability to move in multiple directions, a 5 Axis CNC Machining Center can machine complex shapes that would be impossible or extremely time-consuming to achieve on a 3-axis machine.

Enhanced surface finishes: The continuous motion of the tool and workpiece results in smoother surface finishes, which is crucial for applications like aerospace and medical components.

For manufacturers or companies seeking the best 5 Axis CNC Machining Service, understanding these advantages is crucial for selecting the right provider for your needs.

When selecting a 5 Axis CNC Machining Service, several factors need to be considered to ensure that the provider can meet your specific requirements. Below are the key factors to keep in mind:

The experience of a CNC machining service provider is one of the most critical aspects of choosing the right service. A company with extensive experience in providing 5 Axis CNC Machining Services will have a proven track record of delivering high-quality results. Look for a service provider that has experience working with the materials you are using, whether it be metals, composites material glass, or other specialized materials.

Fujian RBT Intelligent Equipment Co., Ltd. is an excellent example of a company with over 24 years of experience in CNC machining. RBT has built a reputation for providing cutting-edge 5 Axis CNC Machining Centers with a focus on high precision, reliability, and customer satisfaction. With their vast expertise, they are a trusted choice for a wide range of industries, from aerospace to medical device manufacturing.

Quality assurance is an essential part of any manufacturing process, and it becomes even more important in 5 Axis CNC Machining Services due to the complexity and precision involved. Ensure that the service provider uses strict quality control measures and has certifications that demonstrate their commitment to quality. Look for certifications such as ISO 9001, which indicates that the provider adheres to internationally recognized quality management systems.

Fujian RBT Intelligent Equipment Co., Ltd. operates with high-quality standards, ensuring that all 5 Axis CNC Machining Parts are produced with precision. Their commitment to quality has earned them a strong reputation globally, with customers across various sectors benefiting from their exceptional services and products.

The capabilities of the 5 Axis CNC Machining Center itself should align with your project needs. Not all 5 Axis CNC machines are created equal, so it’s important to select a service provider that has state-of-the-art equipment capable of handling your most complex tasks. Consider the following:

Size and capacity: Ensure that the CNC machine can accommodate the size and weight of your parts.

Precision: The 5 Axis CNC Machining Center should be capable of achieving the necessary tolerances for your project.

Multi-material capabilities: Can the provider handle the specific materials you need, such as composites material glass or high-strength alloys?

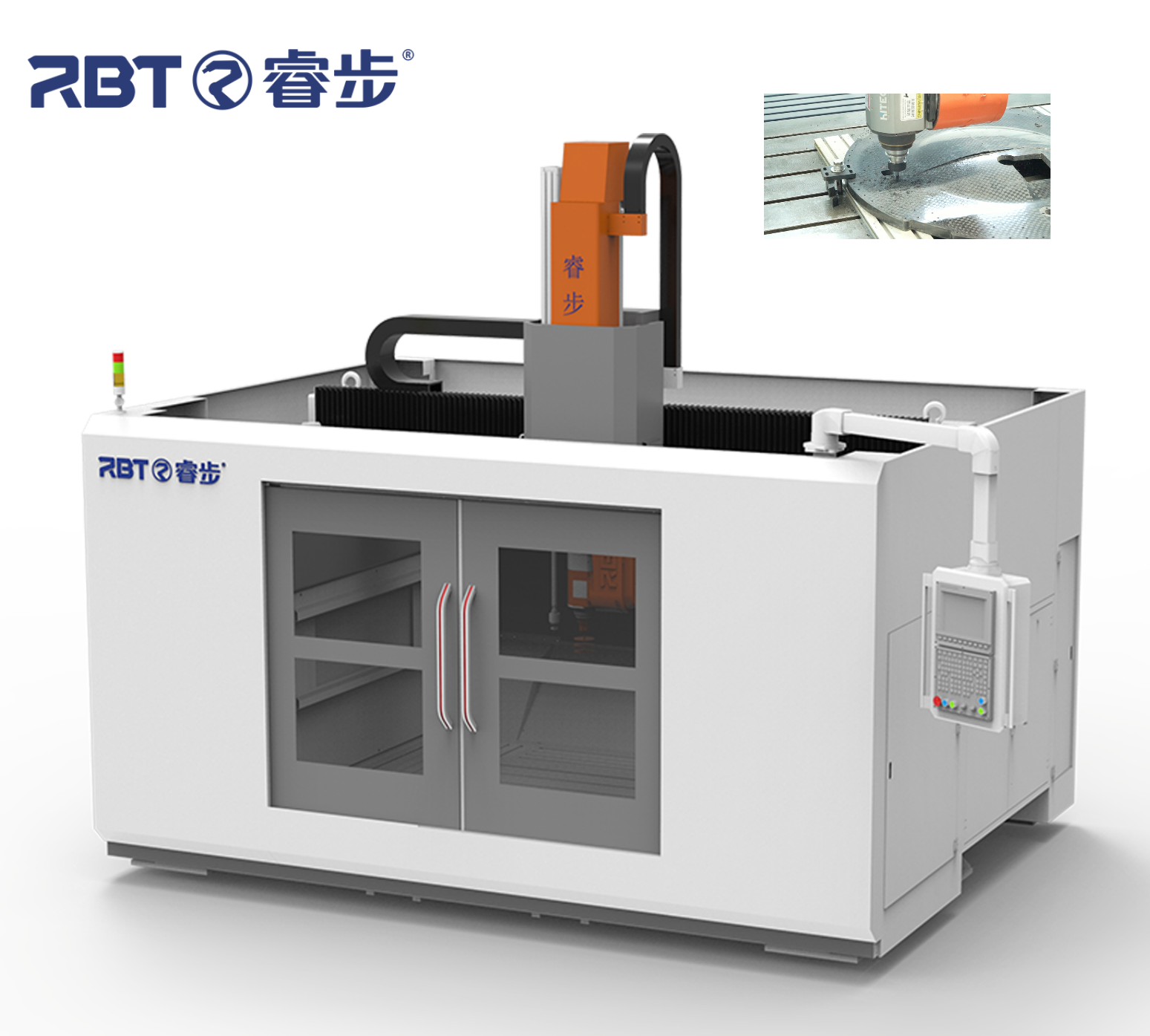

RBT provides a comprehensive range of 5 Axis CNC Machining Centers with various configurations, such as gantry-style, truss-style, and fully enclosed systems, offering flexibility to meet different customer needs. Whether you need a machine for precise aerospace components or advanced composite materials, RBT can deliver tailored solutions.

The best 5 Axis CNC Machining Services integrate advanced software for design and simulation, ensuring that parts are machined accurately before any physical work begins. Make sure that the service provider uses up-to-date CNC software that allows for detailed simulations and optimizations. This will ensure that the final product meets all required specifications.

Fujian RBT uses cutting-edge software solutions integrated with their 5 Axis CNC Machining Centers, ensuring that your parts are not only designed to meet your requirements but also simulated to guarantee precision before machining begins.

Turnaround time is a key factor when choosing a CNC service. The best 5 Axis CNC Machining Services can deliver high-quality parts within a reasonable time frame. Make sure to inquire about the provider’s production capacity and lead times, especially if you are working on time-sensitive projects. If you need large volumes of parts, make sure that the service provider can handle the required volume without compromising quality.

RBT’s production capacity is vast, with the company capable of handling both small and large-volume orders. With a monthly production capacity that exceeds 500,000 units, RBT is well-equipped to meet urgent deadlines and bulk orders, ensuring your parts are delivered on time.

Cost is always a critical consideration when selecting a CNC service provider. While 5 Axis CNC Machining Services can be more expensive than 3-axis machining, the benefits of increased precision and reduced setup time can justify the higher cost in many cases. When evaluating cost, consider not only the per-part machining cost but also the potential savings from reduced production time and fewer errors.

RBT offers highly competitive pricing for their 5 Axis CNC Machining Services, providing excellent value for their advanced technology and high precision. Their cost-effective solutions can help businesses stay within budget while maintaining the highest standards of quality.

Some service providers offer additional post-machining services, such as assembly, finishing, and inspection. These additional services can help streamline your production process and ensure that your parts are delivered ready for use. Make sure to ask the provider about any post-machining services they offer and how they can help your business.

RBT offers comprehensive post-machining services, including quality inspections, surface finishing, and final assembly, ensuring that the parts meet the required specifications and are ready for final use. This added value helps companies save time and reduce the risk of defects.

A reputable 5 Axis CNC Machining Center Manufacturer will offer excellent customer support both during and after the machining process. Inquire about the company’s after-sales service, warranty, and support for any potential issues that may arise with the finished parts.

Fujian RBT is known for its exceptional customer service, offering robust after-sales support, including training, maintenance, and quick troubleshooting. Their commitment to customer satisfaction ensures that clients receive the highest level of support throughout the entire process.

When looking to buy a 5 Axis CNC Machining Center for Sale, you should also evaluate the 5 Axis CNC Machining Center Manufacturer to ensure that the machine meets your business needs. Key factors to consider include:

Machine specifications: Ensure that the CNC machine has the features necessary to handle your manufacturing requirements, including precision, size, and multi-axis capabilities.

Reputation and reviews: Check reviews and ratings from other customers who have used the manufacturer’s equipment.

Support and service: Ensure that the manufacturer offers support services like training, maintenance, and technical support to keep the equipment running smoothly.

Pricing and financing options: Consider the total cost of ownership, including the initial purchase price, installation, training, and ongoing maintenance.

RBT provides a variety of CNC machines for sale, offering excellent support and training to help companies maximize their investment in 5 Axis CNC Machining Centers.

Q1: What are the advantages of using 5 Axis CNC Machining Services over 3 Axis CNC machining?

A1: 5 Axis CNC Machining Services offer superior precision, reduced setup time, and the ability to machine complex parts that are difficult or impossible to produce using 3-axis machines.

Q2: How do I know if a 5 Axis CNC Machining Center is right for my project?

A2: If your project involves complex geometries, tight tolerances, or multi-directional cutting, a 5 Axis CNC Machining Center is likely the best choice.

Q3: What is the typical cost of 5 Axis CNC Machining Services?

A3: The cost of 5 Axis CNC Machining Services depends on factors such as material, part complexity, and production volume. It’s important to get a quote from the service provider for a more accurate cost estimate.

Q4: How can I ensure the quality of the parts produced by a 5 Axis CNC Machining Service?

A4: Ensure that the service provider follows strict quality control measures, offers certifications like ISO 9001, and uses advanced software to simulate the machining process before physical production.

By carefully considering these factors and working with an experienced provider like Fujian RBT Intelligent Equipment Co., Ltd., you can select the best 5 Axis CNC Machining Service for your project, ensuring high-quality results delivered on time and within budget.