Views: 0 Author: Site Editor Publish Time: 2024-12-16 Origin: Site

In the world of precision machining, CNC machining centers play an essential role in producing high-quality components for various industries, including aerospace, automotive, medical, and electronics. When it comes to choosing the right machining center for a particular project, many engineers and manufacturers must decide between 5 Axis CNC Machining Centers and 3 Axis CNC Machining Centers. Each of these machines has distinct capabilities that make them suited for different types of operations. In this article, we will explore the key differences between these two types of CNC machining centers, discuss their applications, and help you make an informed decision on which is best for your needs.

A 3 Axis CNC Machining Center is one of the most commonly used machines in the manufacturing industry. As the name implies, it operates along three linear axes: the X-axis, Y-axis, and Z-axis. These three axes control the movement of the cutting tool, enabling it to cut or shape the material in a variety of directions.

3 Axis CNC Machining Centers are ideal for machining parts with relatively simple geometries and features. Some typical applications include:

Milling: Cutting flat surfaces, slots, holes, and pockets.

Drilling: Creating accurate holes for screws, bolts, and fasteners.

Basic part manufacturing: Used for producing standard components that do not require complex geometry.

While 3 Axis CNC Machining Centers are versatile, their primary limitation is that they are confined to a single plane of motion. This makes them unsuitable for parts with intricate angles, complex curves, or unusual shapes.

A 5 Axis CNC Machining Center offers significantly more flexibility compared to its 3-axis counterpart. It operates along five axes of movement: the X, Y, and Z axes, plus two rotational axes that allow the workpiece to rotate about the X-axis and Y-axis. This added degree of freedom enables a 5 Axis CNC Machining Center to handle much more complex and intricate parts with ease.

5 Axis CNC Machining Centers are ideal for machining highly complex and precise parts that require multi-dimensional cuts. These machines are used in industries such as aerospace, medical, automotive, and high-precision manufacturing. Typical applications include:

Aerospace components: Parts with complex geometries such as turbine blades or aircraft wing structures.

Medical implants: Intricate, customized components like knee implants, hip replacements, and dental tools.

Automotive: Complex engine components and parts for high-performance vehicles.

Molds and dies: Production of intricate and high-precision molds used in plastic injection molding and die casting.

The ability to manipulate both the tool and the workpiece simultaneously makes 5 Axis CNC Machining Centers suitable for achieving superior surface finishes and machining tight tolerances.

The most fundamental difference between these two machines is the number of axes they operate on. 3 Axis CNC Machining Centers operate along three linear axes (X, Y, and Z), while 5 Axis CNC Machining Centers incorporate two additional rotational axes (often referred to as the A-axis and B-axis). This added movement allows for more precise and versatile machining, enabling the production of much more complex parts.

While 3 Axis CNC Machining Centers are suitable for basic, less complex parts, 5 Axis CNC Machining Centers excel in producing intricate geometries. With a 5 Axis CNC Machining Center, manufacturers can machine parts from multiple angles without the need to reposition the workpiece, reducing setup time and improving accuracy. For instance, in the aerospace industry, 5 Axis CNC Machining Centers are crucial for producing turbine blades that require cutting from various directions and angles.

The extra axes in a 5 Axis CNC Machining Center provide greater precision, enabling the machining of parts with tighter tolerances and more complex features. Moreover, the continuous movement of the tool and the workpiece can produce superior surface finishes. For components requiring high-quality, smooth surfaces such as those used in medical implants or aerospace parts, 5 Axis CNC Machining Centers are often the preferred choice.

While 3 Axis CNC Machining Centers are generally faster for simple tasks due to their limited range of motion, 5 Axis CNC Machining Centers can perform the same tasks with greater efficiency by reducing the need for tool changes and repositioning of the workpiece. This makes 5 Axis CNC Machining Centers a more efficient choice for complex parts, as they can reduce production time and eliminate the need for multiple machines or setup adjustments.

The most significant downside of 5 Axis CNC Machining Centers is their cost. They are more expensive to purchase, operate, and maintain compared to 3 Axis CNC Machining Centers. The added complexity, precision, and versatility come at a price, which may be a significant factor for small to medium-sized businesses. However, for companies that require high-precision or complex parts, the investment in a 5 Axis CNC Machining Center may be well worth it in the long run.

One of the notable applications of 5 Axis CNC Machining Centers is in the processing of materials that are difficult to machine with traditional methods. 5 Axis CNC Machining Centers for Composites Material Glass are particularly valuable in industries that work with composite materials, including automotive, aerospace, and medical sectors.

Composites Material Glass typically requires intricate machining due to its hardness and brittleness. A 5 Axis CNC Machining Center allows for the precise cutting and shaping of composite materials by positioning the tool at multiple angles and optimizing the cutting process to prevent material breakage. This ensures that manufacturers can produce high-quality composite parts, such as structural components for aircraft or medical devices, with minimal waste.

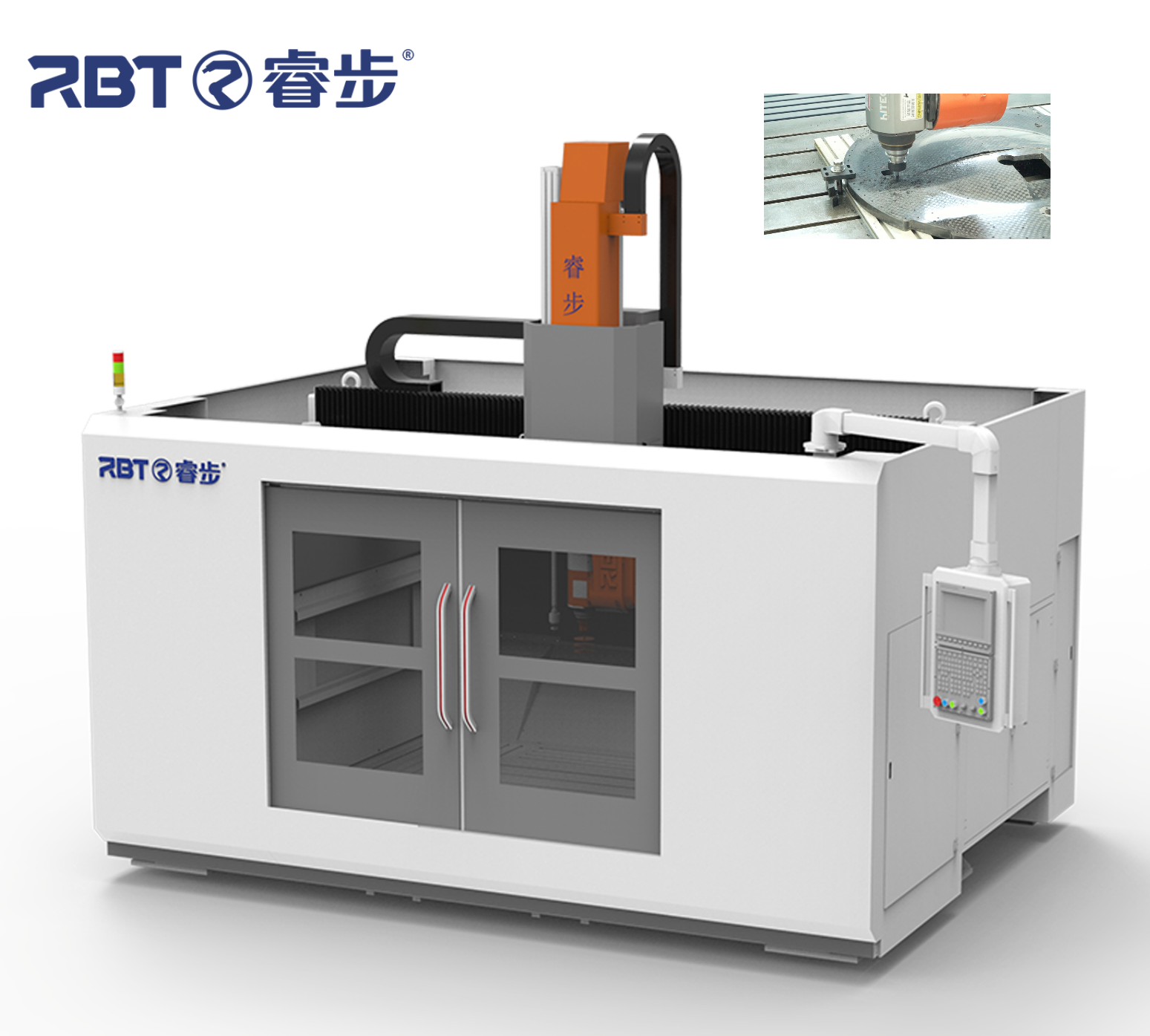

Fujian RBT Intelligent Equipment Co., Ltd., a leader in the CNC machining industry, offers advanced CNC machining solutions that cater to a wide range of industries. The company specializes in high-speed precision five-axis CNC machining centers, making them an ideal choice for manufacturers requiring complex, high-precision components. With over 24 years of experience, RBT has established itself as a trusted 5 Axis CNC Machining Center manufacturer, known for its commitment to quality, innovation, and competitiveness.

As a solution provider, RBT not only manufactures 5 Axis CNC Machining Centers but also offers 5 Axis CNC machining services, helping businesses optimize their production processes. The company's ability to provide customized CNC machining services ensures that each project, whether it involves composites material glass or aerospace components, receives the precision and efficiency it requires.

When it comes to selecting a 5 Axis CNC Machining Center Manufacturer, it’s crucial to choose a provider with the necessary expertise, technology, and capabilities. Fujian RBT Intelligent Equipment Co., Ltd. stands out as a leader in the CNC machining field, offering both the latest technology and unmatched customer service. Their 5 Axis CNC machining services can be tailored to meet the specific needs of various industries, ensuring that clients receive top-quality results on every project.Look for manufacturers that provide a comprehensive suite of services, including:

Engineering support: Assisting with design modifications and custom solutions.

Rapid prototyping: Quickly producing prototypes for testing and evaluation.

Advanced material handling: Working with a variety of materials such as composites, metals, and plastics.

Post-machining services: Offering finishing, assembly, and quality control checks to ensure the parts meet all specifications.

Fujian RBT's global after-sales support ensures that clients have access to assistance no matter where they are located, making them an ideal partner for businesses seeking high-quality, reliable CNC machining solutions.

Q1: What is the primary advantage of a 5 Axis CNC Machining Center over a 3 Axis CNC Machining Center?

A1: The primary advantage of a 5 Axis CNC Machining Center is its ability to machine complex shapes from multiple angles without repositioning the workpiece, reducing setup time and increasing precision, especially for intricate parts.

Q2: Can a 5 Axis CNC Machining Center be used for machining composites material glass?

A2: Yes, 5 Axis CNC Machining Centers for Composites Material Glass are designed to handle complex cutting and shaping tasks, allowing for high-precision machining of hard, brittle materials like composites and glass.

Q3: Are 3 Axis CNC Machining Centers still relevant in modern manufacturing?

A3: Yes, 3 Axis CNC Machining Centers are still widely used for simpler, high-volume machining tasks where complex geometry is not required. They offer a cost-effective solution for basic part production.

Q4: How much does a 5 Axis CNC Machining Center cost?

A4: The cost of a 5 Axis CNC Machining Center varies widely depending on the brand, features, and capabilities. On average, you can expect to pay significantly more for a 5 Axis CNC Machining Center compared to a 3 Axis CNC Machining Center.

Q5: Can I find affordable 5 Axis CNC machining services?

A5: Yes, there are many providers like Fujian RBT Intelligent Equipment Co., Ltd. that offer 5 Axis CNC machining services at competitive prices. They can provide tailored solutions to meet your budget and requirements.

Both 3 Axis CNC Machining Centers and 5 Axis CNC Machining Centers have their distinct advantages and are suitable for different manufacturing needs. If your project involves complex, high-precision parts with intricate geometries, a 5 Axis CNC Machining Center will likely be the better choice. For more straightforward tasks, a 3 Axis CNC Machining Center remains an efficient and cost-effective option.

With Fujian RBT Intelligent Equipment Co., Ltd. offering cutting-edge 5 Axis CNC Machining Centers and a range of specialized services, manufacturers have access to world-class solutions that can enhance precision, reduce production time, and improve the overall quality of their components. Whether you're working with composites material glass or aerospace components, RBT’s technology and expertise can help you achieve optimal results.